Applications of Perforated Metal Mesh: Diverse Uses

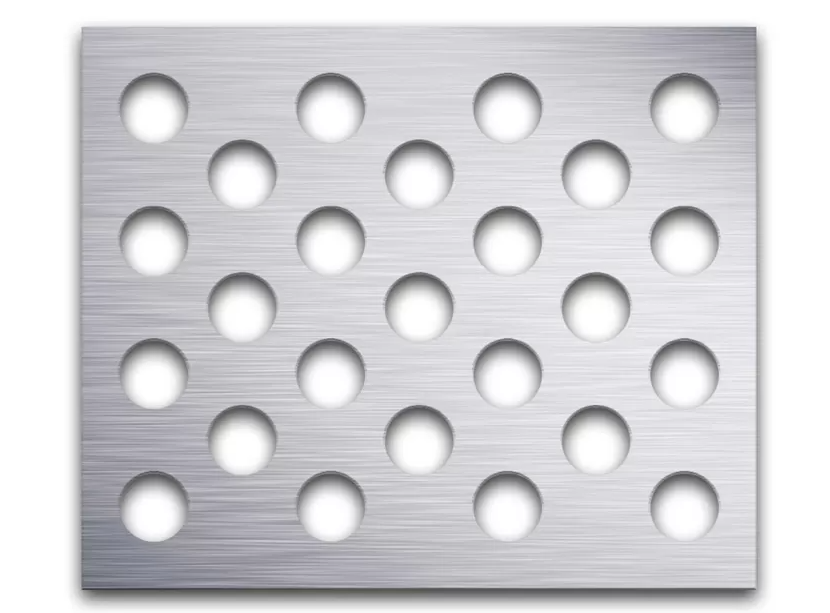

Perforated metal mesh is a versatile material made from thin sheets of metal with a series of holes or perforations punched through them. These holes can vary in size, shape, and pattern, making perforated metal mesh an adaptable solution for many different applications across multiple industries. Whether used for aesthetic, functional, or structural purposes, perforated metal mesh continues to be a popular choice for a variety of uses. In this article, we explore the diverse applications of perforated metal mesh and why it’s such a valuable material in today’s market.

1. Architectural and Design Applications

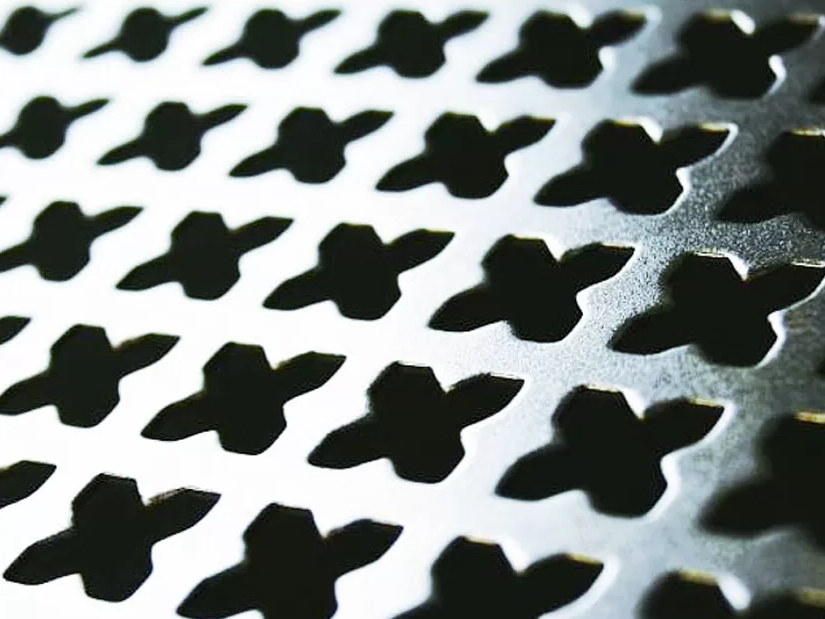

One of the most popular uses for perforated metal mesh is in architecture and design. Due to its aesthetic appeal and customizable options, architects often use perforated metal to create decorative facades, screens, and partitions in buildings. The various hole patterns and finishes allow for endless design possibilities, giving structures a modern and unique appearance.

In addition to its visual appeal, perforated metal mesh also allows for natural light and ventilation to pass through, making it an ideal material for energy-efficient buildings. It can be used in:

Exterior facades: Perforated metal can create visually striking facades that allow airflow and reduce solar heat gain.

Ceilings and partitions: It’s often used to design soundproofing solutions, offering both acoustic benefits and aesthetic value.

Railings and barriers: Decorative railing systems made from perforated metal provide a combination of security and style.

2. Industrial and Safety Applications

Perforated metal mesh is widely used in industrial applications where strength and functionality are key. Its durability makes it ideal for creating protective barriers, machine guards, or even components in manufacturing equipment. Some common industrial applications include:

Machine guards: Perforated metal mesh is used to enclose machinery or tools, providing safety by preventing accidents while allowing for airflow and visibility.

Dust collection systems: The material is used to make filters or collection devices that separate dust and other particles from industrial exhausts.

Walkways and platforms: When used in industrial flooring, perforated metal mesh provides a slip-resistant surface while maintaining strength and support for heavy equipment and foot traffic.

Ventilation panels: Perforated sheets are often used as grilles or panels to allow air to flow through industrial enclosures or electrical cabinets.

3. Agricultural Applications

In agriculture, perforated metal mesh plays an important role in many different processes. Its durability, flexibility, and ease of use make it a popular choice in farming and livestock applications. Some agricultural uses of perforated metal mesh include:

Animal cages and enclosures: The mesh is ideal for constructing strong, long-lasting cages for small animals, birds, and other livestock, providing ventilation while maintaining security.

Drainage systems: Perforated metal can be used in agricultural drainage systems to filter water or soil, ensuring effective and efficient irrigation.

Seed screens and sorting systems: The mesh is often used in seed sorting applications where different perforation sizes help separate various seed types or materials.

Galvanized Perforated Metal Mesh

4. Filtration Systems

Perforated metal mesh is frequently used as a filtration medium in a wide range of industries. Its unique design, which allows fluids, gases, or particles to pass through while keeping unwanted debris out, makes it ideal for filtration applications. Some examples include:

Water filtration: Perforated metal mesh is often used in water treatment plants as part of filtration systems to remove impurities and particles from water before it is treated or released.

Oil and gas filtration: In the petroleum industry, perforated metal mesh helps filter out solid particles from oil and gas pipelines, keeping systems running smoothly.

Air filters: Perforated metal mesh can be found in HVAC systems, car air filters, and other air filtration applications, helping to ensure that air quality remains high and that systems are free of pollutants.

5. Automotive and Transportation Applications

In the automotive and transportation industries, perforated metal mesh is used for both functional and aesthetic purposes. Some applications in this field include:

Grilles and bumpers: Perforated metal is often used in the manufacturing of vehicle grilles and bumpers, as it offers durability while allowing airflow to engine components.

Soundproofing: The mesh material is commonly used in automotive noise reduction systems, where it absorbs or redirects sound waves, enhancing the comfort of vehicle interiors.

Decorative elements: Perforated metal mesh is also used in automotive design, such as in the creation of stylish vents, trim, and other exterior elements.

6. Retail and Display Applications

In retail and display environments, perforated metal mesh is used to create visually appealing and functional fixtures. Its versatility allows it to be used for a wide variety of display systems and storage solutions, including:

Store shelving: Perforated metal is often used for shelves and display stands, providing a sleek, modern appearance while ensuring strength and durability.

Product displays: Retailers use perforated metal mesh to create eye-catching displays that highlight their products while allowing air circulation and easy visibility.

Security cages: Stores and warehouses may use perforated metal mesh to create secure enclosures for valuable products or sensitive materials.

7. Environmental Applications

Perforated metal mesh can also be used in environmental applications, particularly in energy conservation and pollution control. Some examples include:

Solar panel supports: Perforated metal mesh is used to support solar panels, offering both structural support and the ability to control air circulation for cooling.

Noise barriers: In urban environments, perforated metal is used to construct noise barriers along highways and railroads, helping to reduce noise pollution.

Windbreaks and screens: In agricultural or environmental settings, perforated metal mesh can be used to create windbreaks that reduce soil erosion or protect crops from harsh winds.

8. Art and Sculpture

Perforated metal mesh is increasingly being used by artists and sculptors for creating large-scale installations, public art pieces, and sculptures. The intricate patterns and light effects that can be achieved with perforated metal make it a popular choice for contemporary art pieces. Artists appreciate its ability to manipulate light, shadow, and space, creating a dynamic and interactive experience for viewers.

Conclusion: Versatile and Essential

Perforated metal mesh is an incredibly versatile material, with applications across a wide range of industries and sectors. Whether used for architectural design, industrial safety, filtration, or retail displays, perforated metal mesh provides both functional and aesthetic benefits. Its unique combination of strength, flexibility, and visual appeal makes it an essential material for diverse applications, and its popularity is only expected to grow as new innovations and uses are discovered.

Related Post: Your Quick Guide to Buying Perforated Metal Mesh

-

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China