Welded Wire Mesh vs Woven Wire Mesh: Which Is Better?

When global buyers search for “welded wire mesh vs woven wire mesh”, what they really want to know is not just the difference — they want to know which one is better for their project.

As a professional Chinese wire mesh manufacturer supplying construction, fencing, industrial and architectural markets worldwide, we receive this question almost every day. This guide explains both products in a clear, practical way to help engineers, contractors and importers choose the right solution.

1. What Is Welded Wire Mesh?

Welded wire mesh is produced by electrically welding steel wires at every intersection, forming a strong grid structure.

The wires are arranged in perpendicular rows and columns, then fused together by high-voltage resistance welding. After welding, the mesh can be galvanized, PVC coated, or stainless steel finished.

Key Characteristics

Fixed and rigid structure

Very high strength

Uniform openings

Excellent dimensional accuracy

Common Applications

Concrete reinforcement

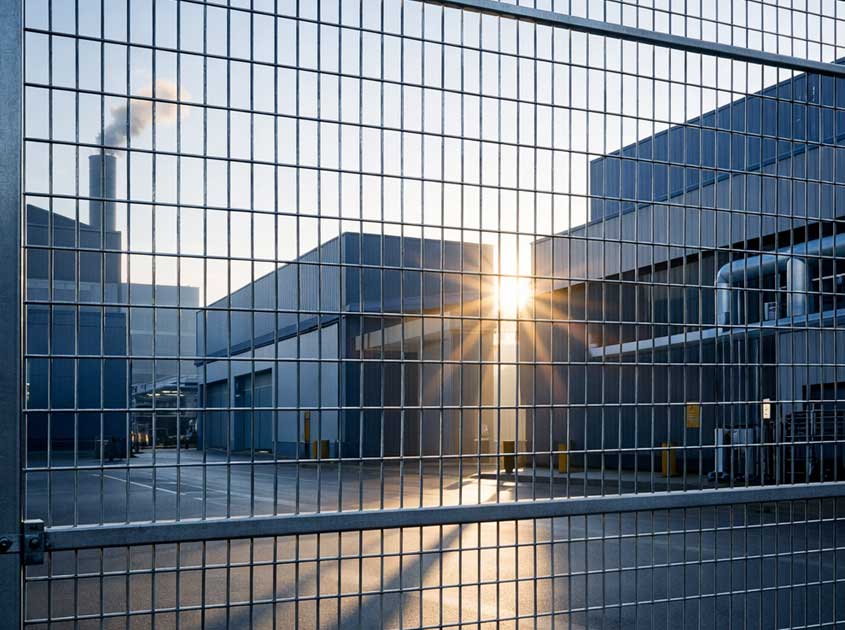

Security fencing

Animal cages

Industrial partitions

Infrastructure projects

Welded mesh is preferred where load, stability, and security are required.

2. What Is Woven Wire Mesh?

Woven wire mesh is made by interweaving individual wires in an over-and-under pattern, similar to fabric weaving.

Instead of being welded, each wire is mechanically woven, allowing flexibility and fine mesh openings.

Key Characteristics

Flexible and elastic

Smooth surface

Precise filtering

Decorative appearance

Common Applications

Filtration and screening

Architectural facades

Decorative panels

Safety guards

Agriculture and mining

Woven mesh is ideal for aesthetic, airflow, and precision.

3. Strength Comparison

Welded wire mesh is structurally stronger because:

Every intersection is permanently fused

Loads are evenly distributed

The mesh does not shift or deform easily

Woven wire mesh relies on wire tension rather than welded joints, so it is:

More flexible

Less rigid under heavy load

If strength and rigidity are required, welded mesh is better.

4. Durability and Coating Performance

Both mesh types can be:

Hot-dip galvanized

Electro galvanized

PVC coated

Stainless steel

However:

Welded mesh must be properly galvanized after welding, otherwise weld points may rust

Woven mesh naturally has no welded joints, making corrosion resistance more uniform

High-quality Chinese manufacturers offer post-weld galvanizing to solve this problem.

5. Installation and Handling

Welded wire mesh:

Holds its shape

Easy to install in frames

Requires less adjustment

Woven wire mesh:

Can be rolled or bent

Easier for curved or custom designs

Needs tensioning when installed

For construction and fencing, welded mesh saves labor.

For architecture and filtration, woven mesh offers more flexibility.

6. Cost Comparison

In most cases:

Welded mesh is more cost-effective for large volumes

Woven mesh costs more for fine openings and stainless steel

The price depends on:

Wire diameter

Mesh opening

Material

Coating

A professional Chinese factory can optimize both types to meet budget targets.

7. Which One Should You Choose?

Choose Welded Wire Mesh if you need:

Structural strength

Security fencing

Concrete reinforcement

Industrial barriers

Choose Woven Wire Mesh if you need:

Filtration

Architectural decoration

Airflow and visibility

Fine screening

There is no universal “better” — only better for your application.

Why Buyers Source Both from China

China offers:

Full production chains

Custom wire sizes

Multiple coating options

Large-scale manufacturing

Competitive pricing

As a professional Chinese wire mesh manufacturer, we produce both welded and woven wire mesh in-house, ensuring:

Stable quality

Fast delivery

Custom specifications

Export-ready packaging

Final Conclusion

Welded wire mesh and woven wire mesh serve different purposes, but both are essential in modern construction, industry, and architecture.

Understanding the differences allows buyers to:

Avoid costly mistakes

Improve project performance

Increase long-term value

When sourced from a reliable Chinese manufacturer, both mesh types deliver high quality, strong performance, and excellent cost efficiency.

If you are choosing between welded and woven wire mesh for your project, working with a factory that produces both gives you the best technical and commercial advantage.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 -

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China