Introduction:

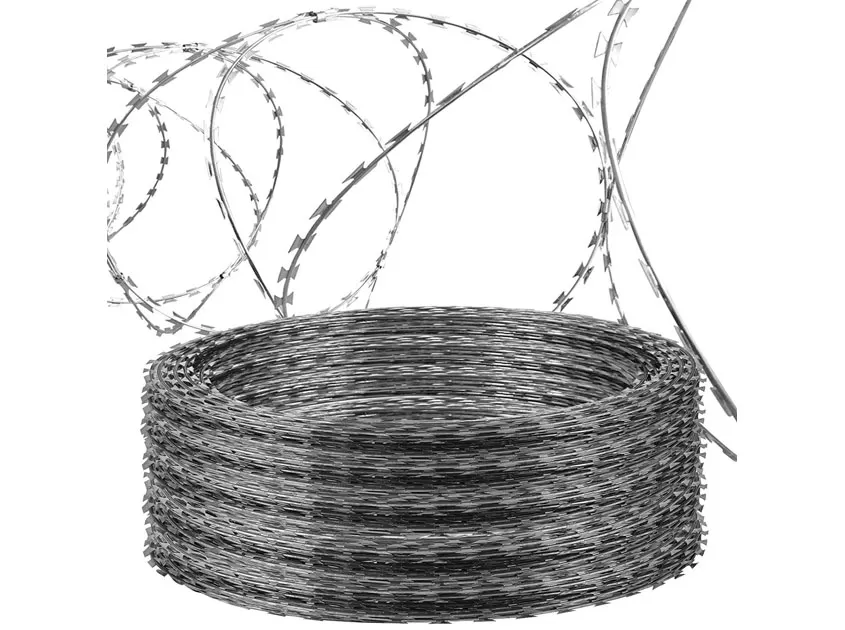

Galvanized Binding Wire can be divided into two categories: electro-galvanized iron wire and Hot dipped galvanized iron wire.

Galvanized Binding Iron Wire:

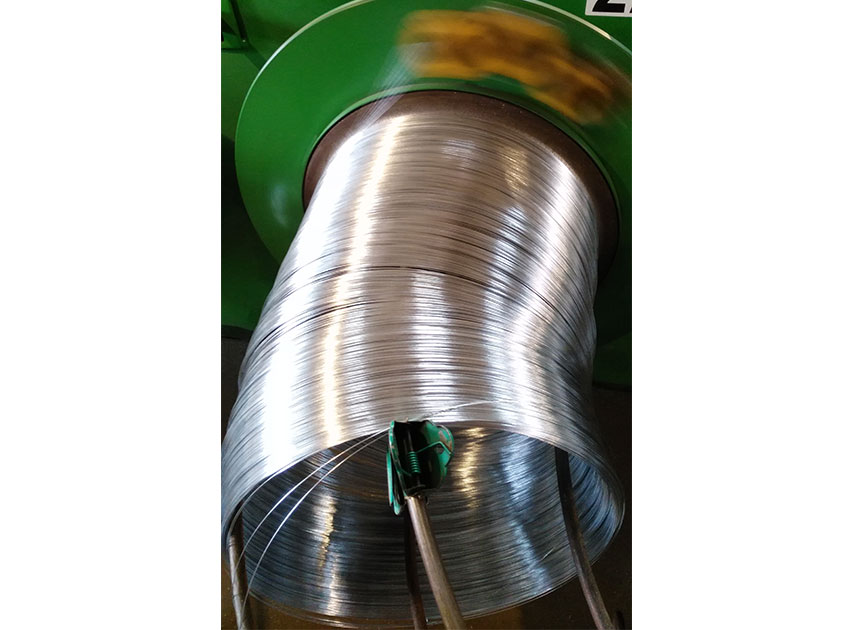

Hot-Dip Galvanized: This wire is dipped in molten zinc, resulting in a thicker zinc coating and higher corrosion resistance.

Electro-Galvanized: The wire is coated with zinc through an electroplating process, which provides a thinner coating compared to hot-dip but is still effective for many applications.

More info.

Galvanized Iron Wire vs. Stainless Steel Wire

Galvanized Iron Wire in Agriculture

Galvanized Iron Wire: A Guide to Maintenance and Lifespan Extension

Features:

High strength: Galvanized binding wire has been specially treated to have high tensile strength and bending strength, and can withstand greater weight and pressure.

Corrosion resistance: The galvanized layer can effectively protect the metal wire from corrosion, allowing it to maintain good performance in various environments.

Easy to use: Galvanized binding wire usually comes with a plastic handle for easy user operation.

Environmentally friendly: recyclable, reducing environmental pollution.

Specifications:

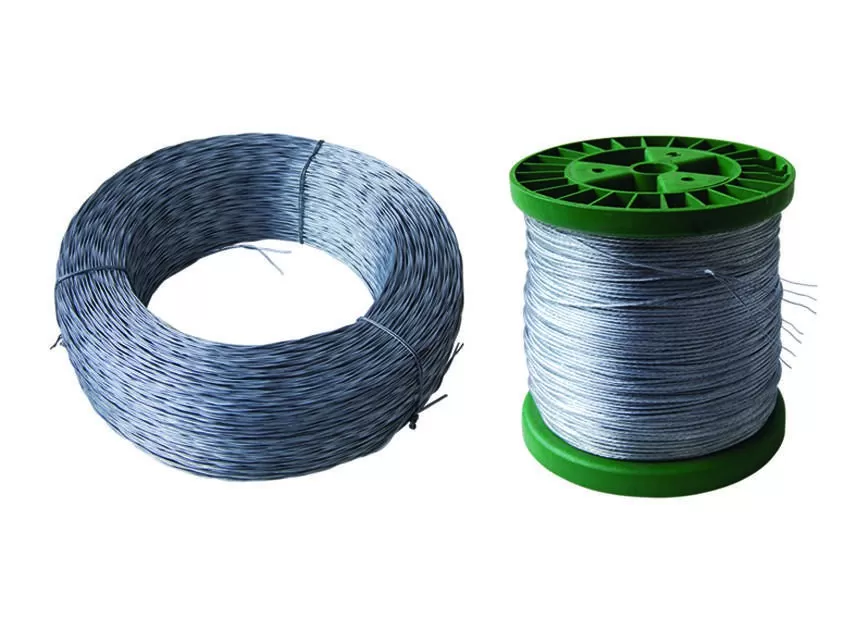

The specifications of Galvanized binding wire usually include diameter, length, and color. Common specifications are 0.45mm diameter, and 1.0mm thickness, and the length can be customized as needed. In terms of color, common ones include white, black, purple, blue, green, etc., which can also be customized according to needs.

| Parameter | Specification |

| Material | High Carbon Steel (Q195, Q235, etc.) |

| Zinc Coating | 20 - 300 g/m² (varies based on type) |

| Diameter Range | 0.6 mm - 5.0 mm |

| Tensile Strength | 300 - 550 N/mm² (depends on application) |

| Elongation | ≥ 10% (varies by product) |

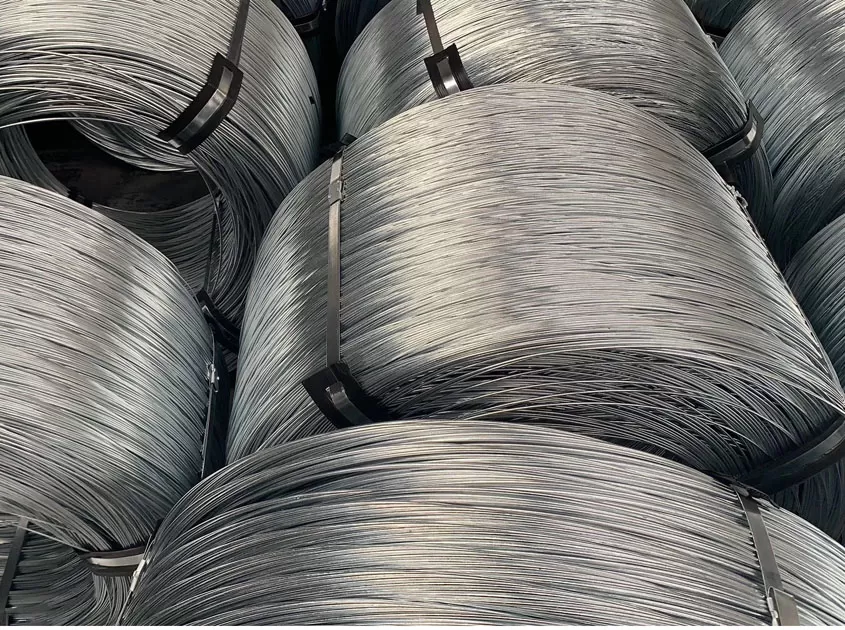

| Coil Weight | 1 kg - 800 kg per coil (customizable) |

| Surface Finish | Smooth, no cracks, even zinc coating |

| Type | Hot-Dip Galvanized, Electro-Galvanized |

| Packaging | Coils, spools, or cut lengths |

| Wire Tolerance | ±0.05 mm (for specific diameters) |

| Application Standards | ASTM A641, BS EN 10244, or equivalent |

| Length per Kilogram | Varies by diameter (e.g., 1.5 mm = ~ 56 m/kg) |

| Corrosion Resistance | High (depends on zinc coating thickness) |

| Color | Bright silver, dull silver (depends on zinc type) |

Note: Special size and specifications can be made according to customers requires.

Technology:

The production process of galvanized iron binding wire includes drawing, galvanizing and cutting of metal wire. Among them, galvanizing is one of the key technologies, which can improve the corrosion resistance and service life of metal wires. At the same time, in order to meet the needs of different uses, Galvanized binding wire can use metal wires of different materials, such as stainless steel, mild steel, etc.

Product Name: Galvanized Binding Wire