Introduction:

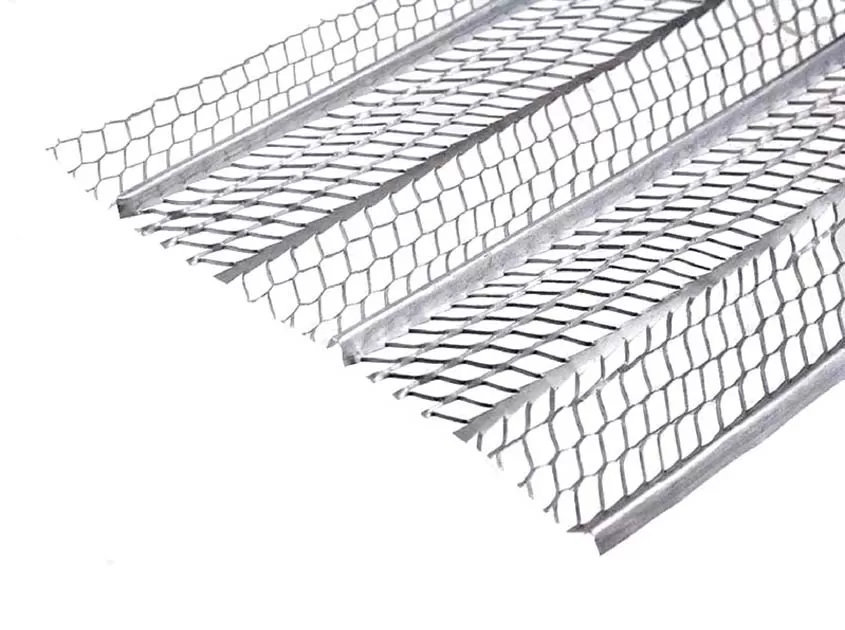

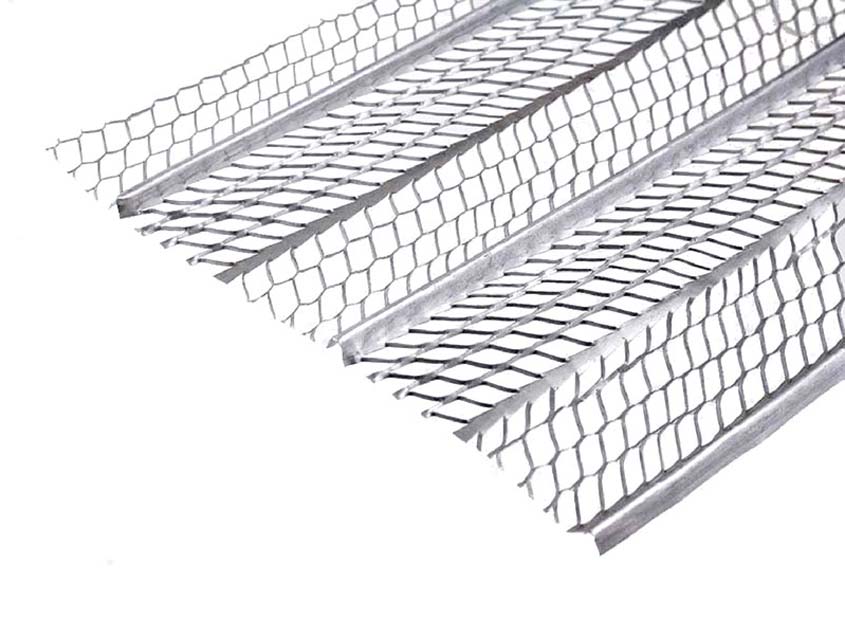

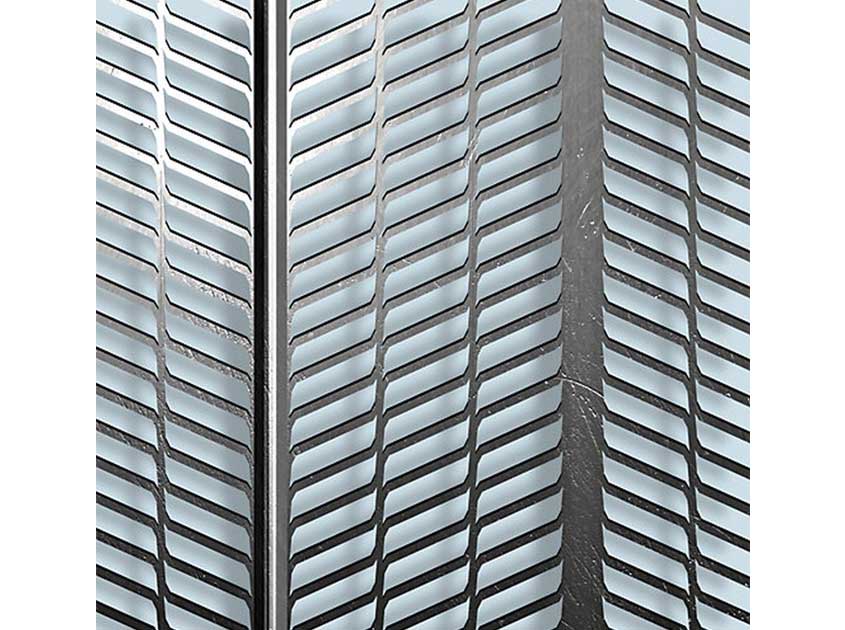

Rib Lath has been widely applied to the concrete structure of projects. It has better stress strength and free shape, it is mostly used as concrete permanent dismantle free template for civil engineering such as tunnel, bridge.

Rib Lath for Concrete is ideal for refurbishing damaged or aged masonry walls when a key for rendering is not certain due to disintegration or softening of the wall face.

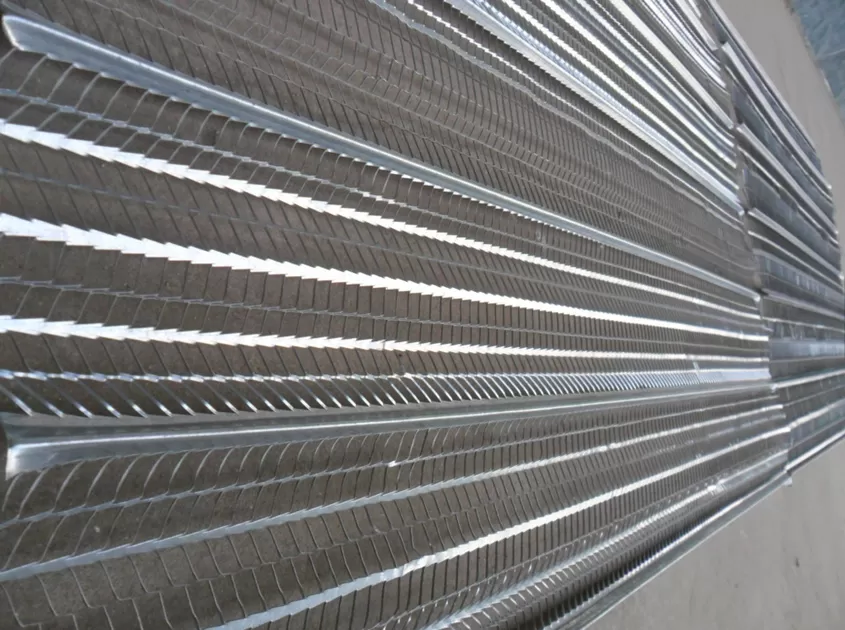

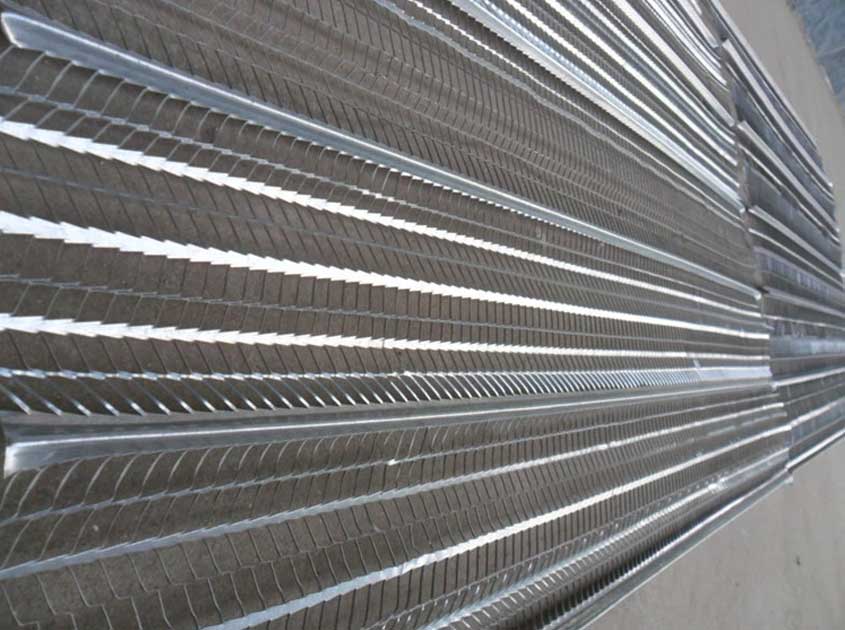

Lath should be fixed with apexes of ribs against the wall, edge ribs of sheets nesting into each other should be wire tied every 15cm and ends of sheets should be lapped not less than 2.5cm and nesting ribs securely tied together.

Stainless steel fixings should be used at sufficient intervals to hold the lath firmly in position.

Features:

1. Material of Rib Lath: hot-dipped galvanized steel sheets

2. Feature of Rib Lath: Excellent engineering quality, and construction security.

3. Application of Rib Lath: It has been widely applied to the concrete structure of projects. It has better stress strength and free shape, it is mostly used as concrete permanent dismantle free template for civil engineering such as tunnels, bridges.

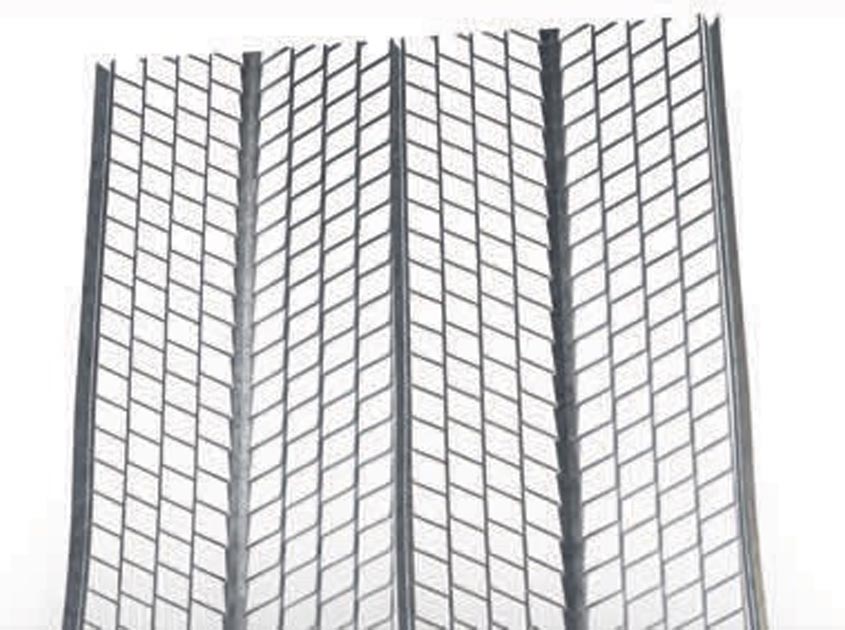

▶ Improved Bonding: The ribbed pattern creates a strong bond between the lath and the applied plaster or render, preventing cracking and detachment.

▶ Lightweight & Easy to Handle: Rib lath is much lighter than solid metal or concrete alternatives, making it easier to transport, cut, and install.

▶ Durability: The galvanized steel or aluminum construction makes rib lath resistant to corrosion, which is particularly important in outdoor or humid environments.

▶ Flexibility: Rib lath can be used on both straight and curved surfaces, making it versatile for different design requirements.

▶ Cost-Effective: Rib lath is an economical choice compared to other plaster base materials, due to its efficiency and reusability.

▶ Fire Resistance: The metal construction and the use of fire-resistant coatings in certain products make rib lath an excellent choice for fire-resistant systems.

Whether for internal plastering, external rendering, or fire protection applications, High Rib Formwork offers significant benefits for a wide variety of construction needs. If you need further details or want guidance on selecting the right type of rib lath for a particular project, feel free to ask!

Specifications:

| Thickness(mm) | Rib Distance(mm) | Weight(KG) | Width X length(mm) |

| 0.30 | 100 | 1.79 | 610 x 2440 |

| 0.35 | 100 | 2.09 | 610 x 2440 |

| 0.40 | 100 | 2.38 | 610 x 2440 |

| 0.45 | 100 | 2.68 | 610 x 2440 |

| 0.5 | 100 | 2.98 | 610 x 2440 |

| Thickness(mm) | Rib Distance(mm) | Weight(KG) | Width X length(mm) |

| 0.30 | 150 | 1.31 | 610 x 2440 |

| 0.35 | 150 | 1.53 | 610 x 2440 |

| 0.40 | 150 | 1.75 | 610 x 2440 |

| 0.45 | 150 | 1.96 | 610 x 2440 |

| 0.5 | 150 | 2.17 | 610 x 2440 |

Note: Special size and specifications can be made according to customers requires.

Technology:

Rib Lath should be fixed with apexes of ribs against the wall, edge ribs of sheets nesting into each other should be wire tied every 15cm and ends of sheets should be lapped not less than 2.5cm and nesting ribs securely tied together.

Stainless steel fixings should be used at sufficient intervals to hold the lath firmly in position.

Product Name: Rib Lath