Introduction:

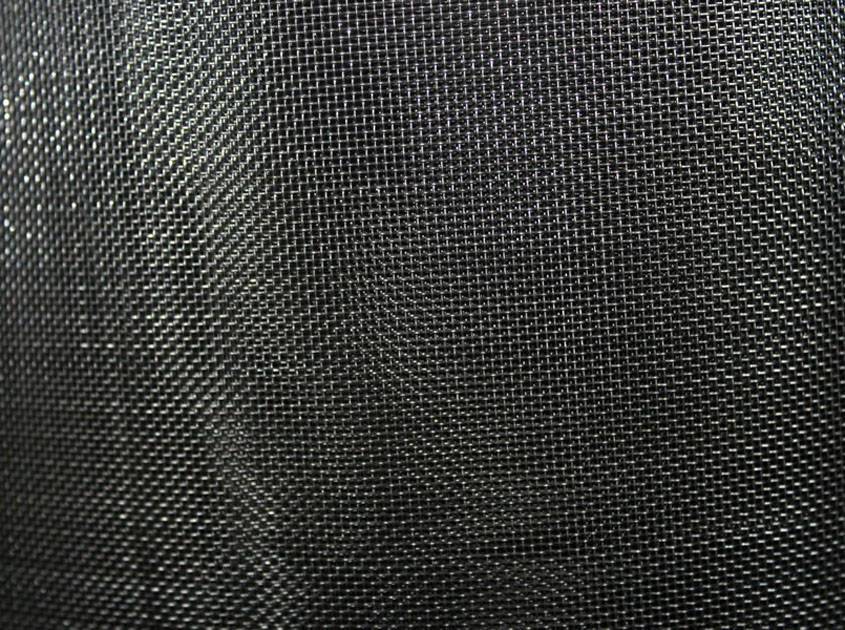

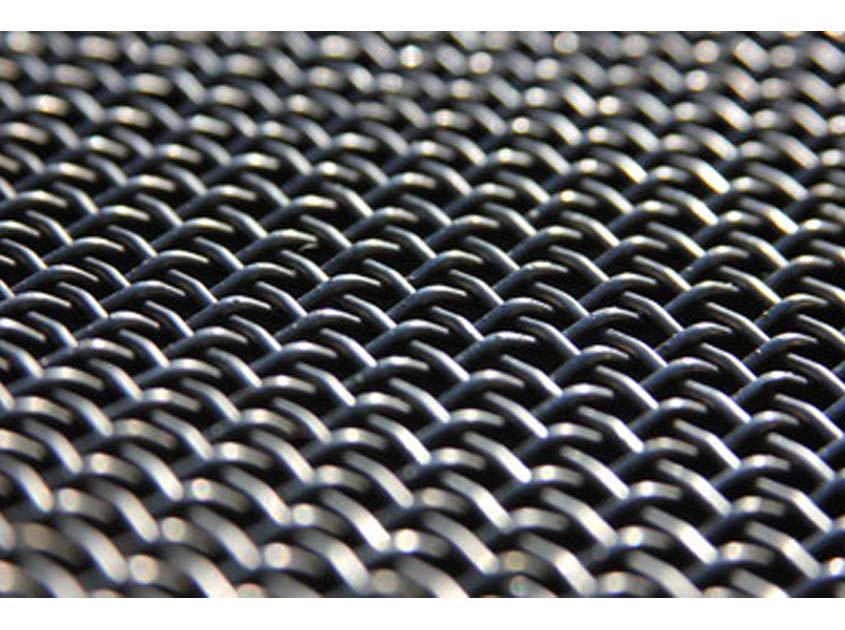

The Black woven wire mesh cloth is a great economical choice for those who are looking for a durable yet inexpensive wire mesh. The black woven wire mesh is one wire mesh, often called as “black wire cloth” or “low carbon steel wire mesh”, and is relatively inexpensive as it is made of plain steel and not heat-treated. This is ideal for clients who are looking for a strong and durable wire mesh where corrosion is not a factor as rust may set in due to its low-carbon steel mesh. The wire mesh is frequently used in fireplace screens, oil strainers, and for small guards. Carbon content is up to 0.3% for mild steel making it a suitable wire to be used for welding, forming, bending, and other engineering applications, as it is neither brittle nor pliable like other wire meshes. Plain steel wire mesh is commonly used as filter wire mesh in several industries including – rubber, grain, and plastic.

Welcome to contact us for black wire cloth custom. We provide you with black wire cloth in different weaves and sizes.

Features:

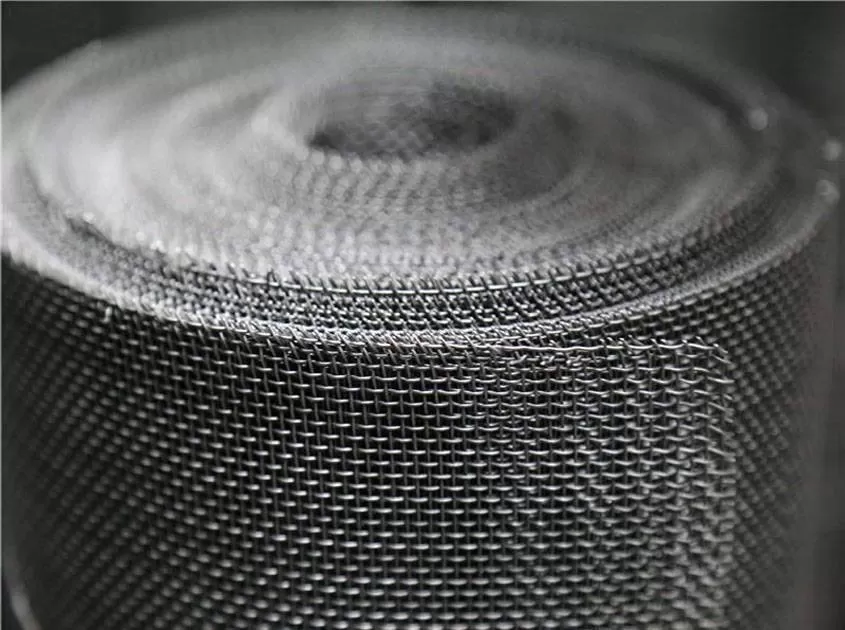

1. Even Meshes:

Black woven wire mesh features uniform and consistent openings, ensuring precise and reliable performance in applications requiring accurate separation, filtration, or screening. The even mesh pattern contributes to the overall efficiency and effectiveness of the mesh in various uses.

2. Smooth Surface:

The smooth surface of black woven wire mesh minimizes friction and wear, reducing the likelihood of damage to materials passing through it. This smoothness also enhances ease of cleaning and maintenance, 4. ensuring that the mesh remains free of debris and contaminants.

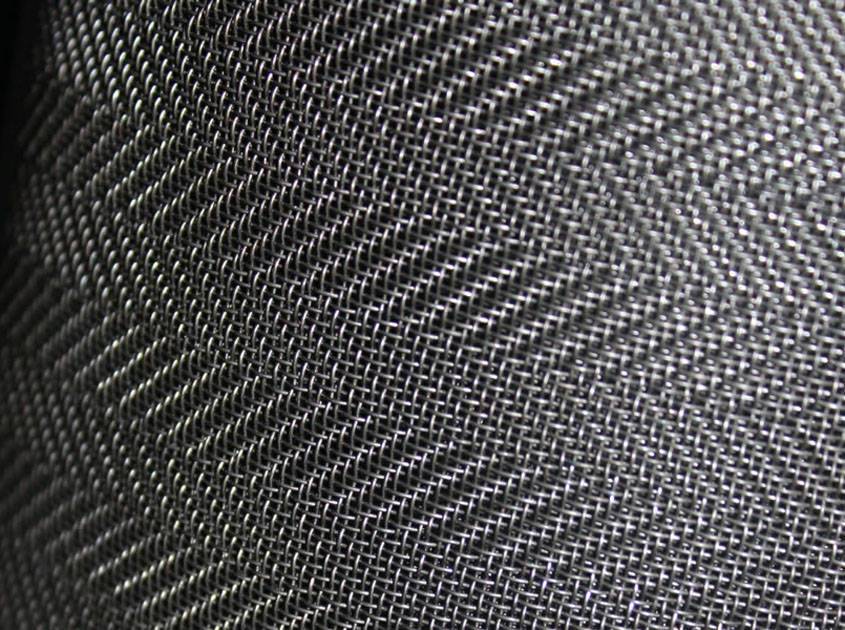

3. Outstanding Filtering Performance:

With its tightly woven structure, black woven wire mesh provides exceptional filtering capabilities, effectively trapping particles and impurities. This high level of filtration is crucial in applications such as water treatment, air purification, and industrial processes where cleanliness is essential.

4. Wide Applications:

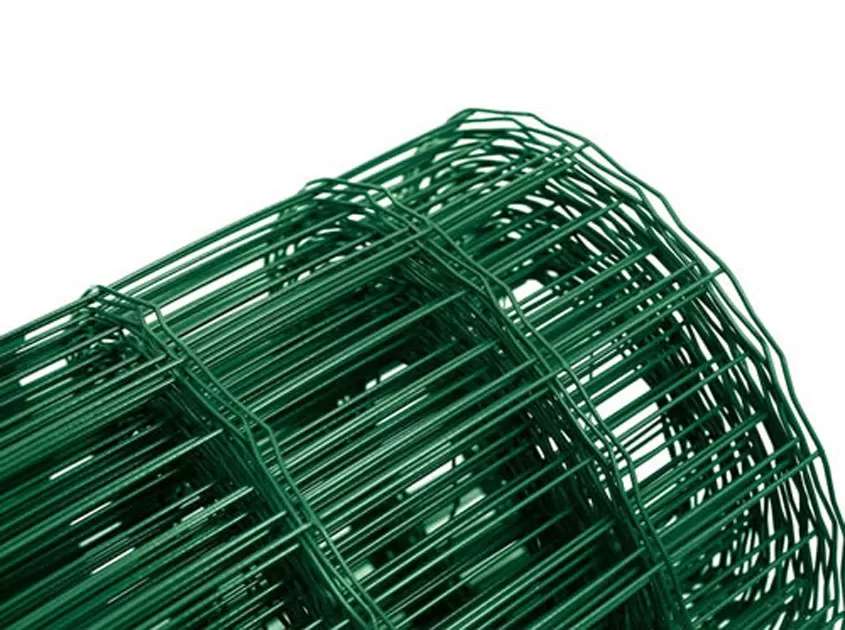

Black woven wire mesh is highly versatile, making it suitable for a broad range of applications. It is commonly used in architectural designs, interior décor, industrial processes, security fencing, and commercial projects. Its adaptability allows it to meet the diverse needs of various industries.

5. Long Service Life:

Constructed from durable materials and often coated for additional protection, black woven wire mesh offers excellent longevity. It withstands harsh environmental conditions, including exposure to chemicals, moisture, and extreme temperatures, ensuring a prolonged service life with minimal maintenance requirements.

6. Low Cost:

Despite its high performance and durability, black woven wire mesh remains cost-effective. Its affordability makes it an attractive option for both large-scale industrial applications and smaller, specialized projects. The low initial cost combined with its long-lasting nature provides excellent value for money.

These detailed descriptions highlight the key advantages of black woven wire mesh, emphasizing its reliability, efficiency, and cost-effectiveness in various applications.

Benefits of Using Black Metal Mesh Over Other Types of Cloths or Meshes:

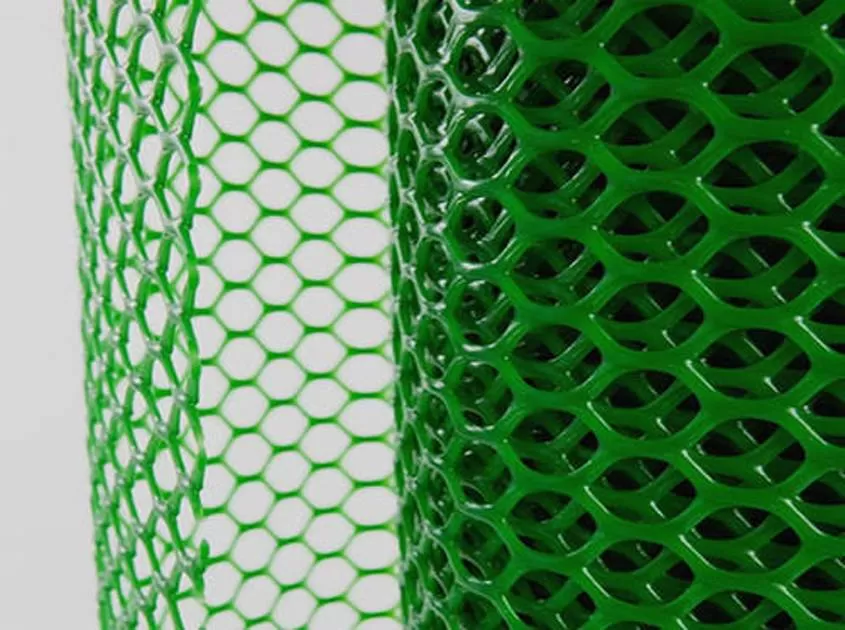

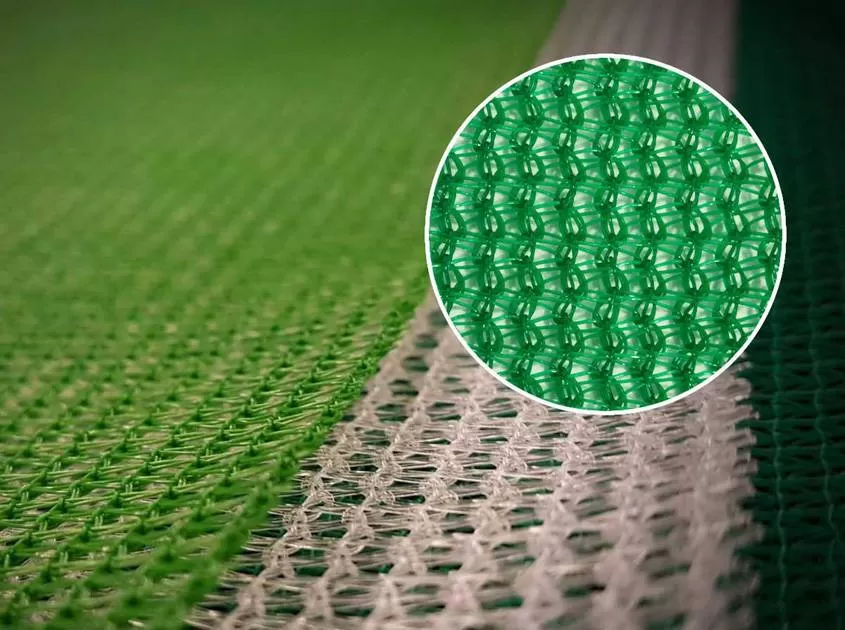

1. Strength and Durability: Epoxy-coated black metal mesh is much stronger and more durable than plastic or aluminum. It resists corrosion, impact, and wear, making it ideal for long-term use. The epoxy coating also makes it easier to clean.

2. Aesthetics: Black metal mesh has a modern, industrial look that enhances contemporary design, adding unique visual interest while serving practical purposes.

3. Versatility: Suitable for a wide range of applications, from architectural and interior design to industrial and commercial settings. It maintains its shape well but may need structural support for covering large areas.

Overall, black metal mesh offers superior strength, durability, aesthetic appeal, and versatility compared to plastic and aluminum meshes.

Specifications:

Specifications of plain weave or twill weave black woven wire mesh.

| Mesh/Inch | Opening (mm) | Wire Diameter (mm) | Reference weight (kg/sq. meter) |

| 10 mesh × 10 mesh | 1.94 | 0.6 | 1.8 |

| 10 mesh × 10 mesh | 1.98 | 0.56 | 1.56 |

| 12 mesh × 12 mesh | 1.52 | 0.6 | 2.16 |

| 12 mesh × 12 mesh | 1.56 | 0.56 | 1.88 |

| 18 mesh × 18 mesh | 0.96 | 0.45 | 1.82 |

| 18 mesh × 18 mesh | 1.0 | 0.41 | 1.52 |

| 18 mesh × 18 mesh | 1.04 | 0.37 | 1.23 |

| 18 mesh × 18 mesh | 1.06 | 0.35 | 1.1 |

| 20 mesh × 20 mesh | 0.86 | 0.41 | 1.68 |

| 20 mesh × 20 mesh | 0.9 | 0.37 | 1.38 |

| 22 mesh × 22 mesh | 0.74 | 0.35 | 1.33 |

| 22 mesh × 22 mesh | 0.79 | 0.30 | 0.99 |

| 24 mesh × 24 mesh | 0.7 | 0.35 | 1.5 |

| 26 mesh × 26 mesh | 0.63 | 0.35 | 1.66 |

| 28 mesh × 28 mesh | 0.6 | 0.31 | 1.36 |

| 30 mesh × 30 mesh | 0.64 | 0.31 | 1.46 |

| 32 mesh × 32 mesh | 0.5 | 0.29 | 1.36 |

| 34 mesh × 34 mesh | 0.47 | 0.28 | 1.3 |

| 36 mesh × 36 mesh | 0.47 | 0.28 | 1.3 |

| 38 mesh × 38 mesh | 0.41 | 0.26 | 1.1 |

| 40 mesh × 40 mesh | 0.39 | 0.25 | 1.2 |

| 40 mesh × 40 mesh | 0.41 | 0.23 | 1.06 |

| 40 mesh × 40 mesh | 0.43 | 0.21 | 0.88 |

| 42 mesh × 42 mesh | 0.365 | 0.24 | 1.1 |

| 44 mesh × 44 mesh | 0.347 | 0.23 | 1.0 |

| 46 mesh × 46 mesh | 0.332 | 0.22 | 1.0 |

| 48 mesh × 48 mesh | 0.319 | 0.20 | 0.96 |

| 50 mesh × 50 mesh | 0.318 | 0.19 | 0.91 |

| 50 mesh × 50 mesh | 0.338 | 0.17 | 0.72 |

| 56 mesh × 56 mesh | 0.248 | 0.17 | 0.81 |

| 60 mesh × 60 mesh | 0.27 | 0.15 | 0.68 |

Specification sheet of dutch weave black woven wire mesh.

| Mesh/Inch | Wire diameter (mm) |

| 12 × 64 | 0.58/ 0.64 |

| 14 × 88 | 0.50/ 0.33 |

| 24 × 110 | 0.36/ 0.25 |

| 30 × 150 | 0.23/ 0.18 |

| 40 × 200 | 0.18/ 0.13 |

Note: Special size and specifications can be made according to customers requires.

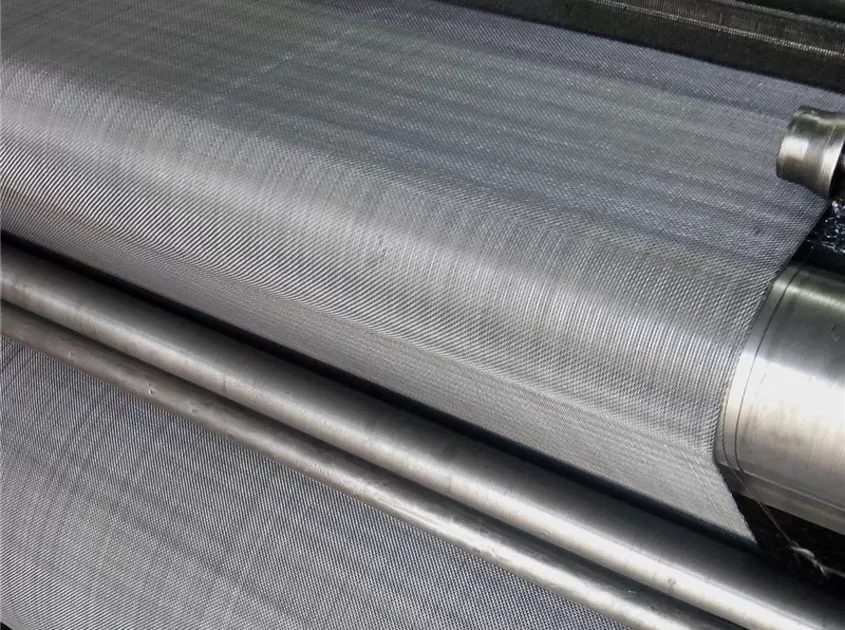

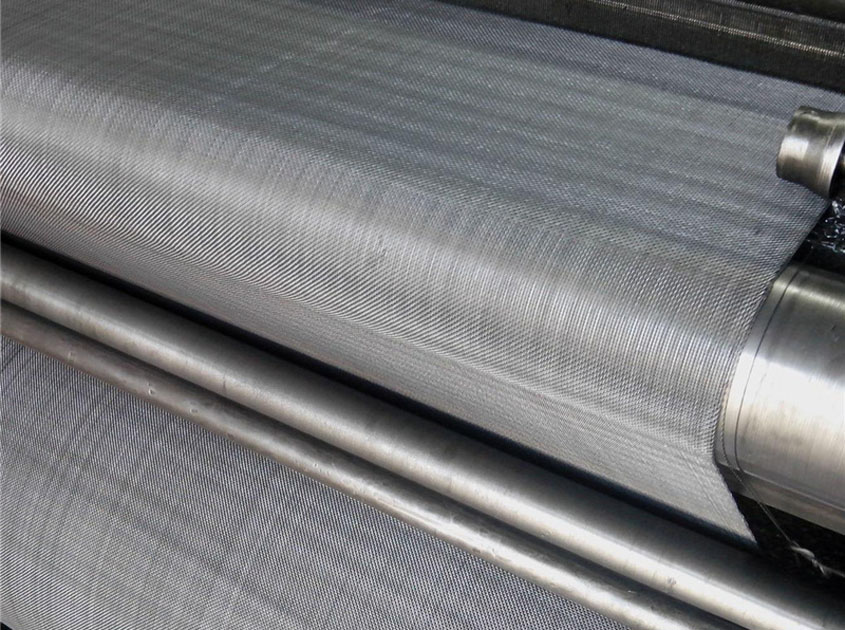

Technology:

Material: low carbon steel wire.

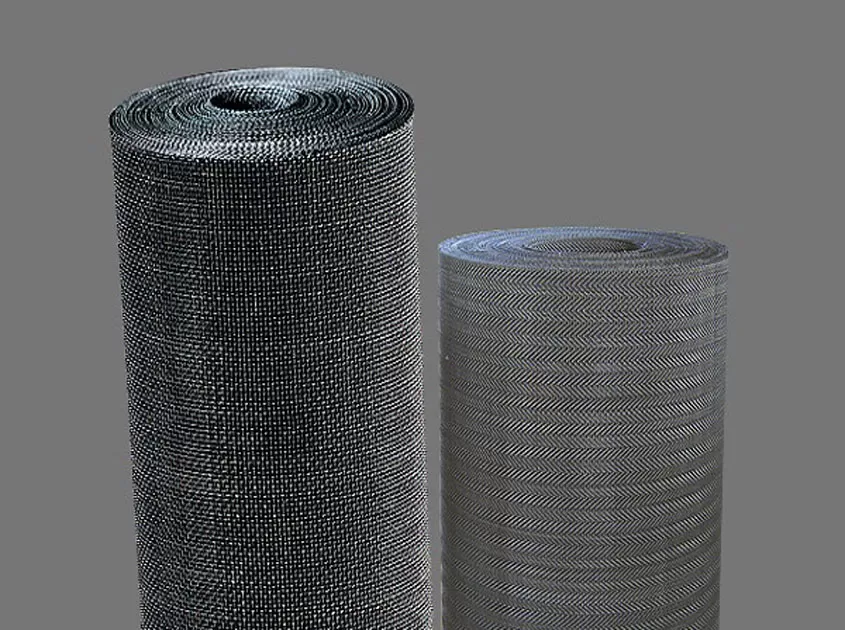

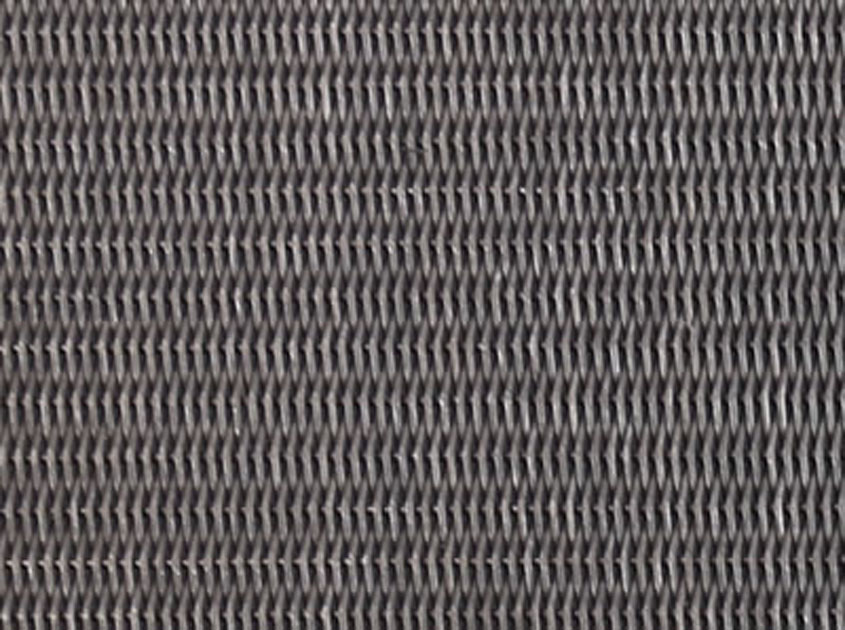

Weaving type: plain weave, twill weave, and dutch weave.

Wire diameter: 0.15mm - 0.6mm.

Mesh sizes:

Plain Weave Black Wire Cloth Custom – Mesh from 6 to 80

Dutch Weave Black Wire Cloth Custom – Mesh from 12 x 64 to 40 x 200

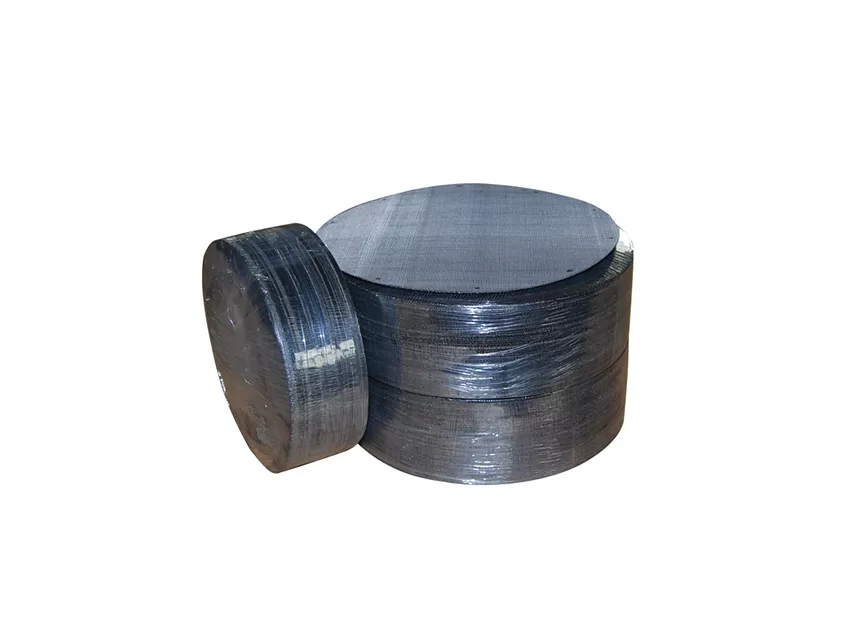

Width: 0.914m - 1.3m.

Length: commonly is 30m, other specs can be customized.

Shape: round, rectangular, square, oval and woven wire cloth.

Product Name: Black Woven Wire Mesh