How to Check the Quality of Welded Wire Mesh

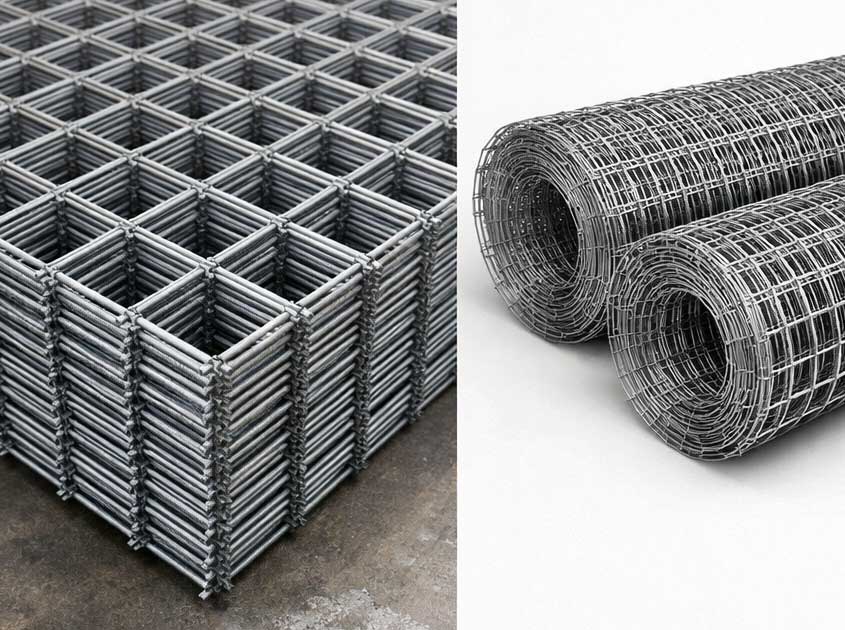

Welded wire mesh is widely used in construction, fencing, agriculture, and industrial applications. However, not all welded wire mesh products offer the same quality. Poor welding strength, incorrect wire diameter, or inadequate surface treatment can lead to structural failure, corrosion, and costly replacements.

This guide explains how to check the quality of welded wire mesh step by step, helping buyers make informed decisions before purchase or shipment.

1. Check the Raw Material Quality

The quality of welded wire mesh starts with the wire itself.

Key points to inspect:

Steel grade consistency

Wire surface smoothness

No cracks, flakes, or contamination

High-quality low-carbon steel or stainless steel ensures better welding performance and durability.

2. Measure Wire Diameter Accuracy

Wire diameter directly affects strength and load capacity.

How to check:

Use a micrometer or caliper

Measure multiple points on the mesh

Compare results with the specification

Even small deviations can reduce strength and violate contract requirements.

3. Inspect Weld Strength at Intersections

Weld quality is the most critical factor.

Methods:

Manual bend test

Light hammer impact

Pull test on intersecting wires

Good welded mesh will:

Not break at the weld

Deform before separation

Show uniform weld marks

Weak welds indicate poor welding current control or inferior materials.

4. Check Mesh Opening Uniformity

Consistent mesh opening ensures easy installation and predictable performance.

Inspection tips:

Measure random openings across the roll or panel

Look for deformation or irregular spacing

Uneven openings suggest poor production control.

5. Examine Surface Treatment Quality

Surface coating determines corrosion resistance.

Galvanized Welded Wire Mesh

Zinc layer should be uniform

No bare spots or peeling

Smooth or slightly spangled finish

PVC Coated Welded Wire Mesh

Strong adhesion between PVC and wire

No cracks or bubbles

Even color distribution

6. Check Zinc Coating Thickness

For galvanized mesh, zinc coating weight is crucial.

Common requirements:

Electro-galvanized: 10–40 g/m²

Hot-dip galvanized: 60–300 g/m²

Thicker zinc coating means longer service life, especially outdoors.

7. Inspect Flatness and Rigidity

High-quality welded wire mesh should:

Lie flat

Maintain shape after handling

Show minimal warping

Poor flatness affects installation and appearance.

8. Review Manufacturing Standards and Certification

Reliable manufacturers comply with:

ISO quality management systems

International or regional standards

Internal quality inspection procedures

Ask for:

Mill test reports

Quality inspection records

Production photos or videos

9. Packaging and Shipping Inspection

Quality inspection does not end with production.

Check:

Protective packaging

Secure bundling

Clear labeling

Proper packaging prevents deformation and coating damage during shipping.

10. Why Choose an Experienced Manufacturer

Professional welded wire mesh manufacturers offer:

Stable raw material sourcing

Automated welding lines

Strict quality control

Export experience

This ensures consistent quality for large or repeat orders.

Conclusion

Checking the quality of welded wire mesh involves:

Raw material inspection

Wire diameter verification

Weld strength testing

Surface treatment evaluation

Packaging assessment

By following these steps, buyers can avoid quality risks and ensure reliable performance in real-world applications. Partnering with a trusted manufacturer further guarantees long-term stability and cost efficiency.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 -

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China