How to Choose Wire Mesh Products for the South American Market

South America is a growing market for wire mesh products, with strong demand across construction, agriculture, industrial applications, and decorative projects. However, entering this market successfully requires understanding regional standards, environmental conditions, and customer expectations. Choosing the right wire mesh products can ensure durability, compliance, and customer satisfaction.

This article provides a comprehensive guide for international buyers and distributors on selecting wire mesh products suitable for the South American market.

1. Understand Regional Standards and Regulations

South American countries often have national building codes and industrial standards that affect wire mesh specifications. Key points include:

Material requirements: Local regulations may dictate corrosion resistance, tensile strength, or safety certifications.

Mesh size and wire diameter: Some countries specify minimum dimensions for fencing, construction reinforcement, or industrial use.

Import documentation: Certificates of origin, material testing reports, and compliance with ISO or ASTM standards are often required for customs clearance.

Working with a manufacturer familiar with South American standards can save time and reduce regulatory risks.

2. Consider Environmental and Climatic Conditions

Environmental factors in South America vary widely, from humid tropical regions to arid deserts. These conditions impact the durability of wire mesh products:

Coastal areas: High humidity and salt exposure require stainless steel or hot-dip galvanized wire mesh.

Tropical rainforests: High humidity and frequent rainfall necessitate corrosion-resistant coatings such as PVC or powder coating.

Inland and arid regions: Standard galvanized mesh may be sufficient for general construction and fencing.

Selecting the right material ensures a longer service life and reduces maintenance costs.

3. Choose the Right Material and Coating

Wire mesh materials commonly used in South America include:

Galvanized steel: Cost-effective and suitable for fencing, construction, and industrial applications.

Stainless steel (304 or 316): Ideal for coastal areas, chemical processing, and high-end architectural projects.

PVC-coated or powder-coated wire mesh: Adds aesthetic appeal and extra corrosion resistance for decorative or outdoor installations.

Discuss material performance and expected lifespan with your manufacturer to meet market requirements.

4. Determine Product Type Based on Application

South America’s market requires different wire mesh types for specific uses:

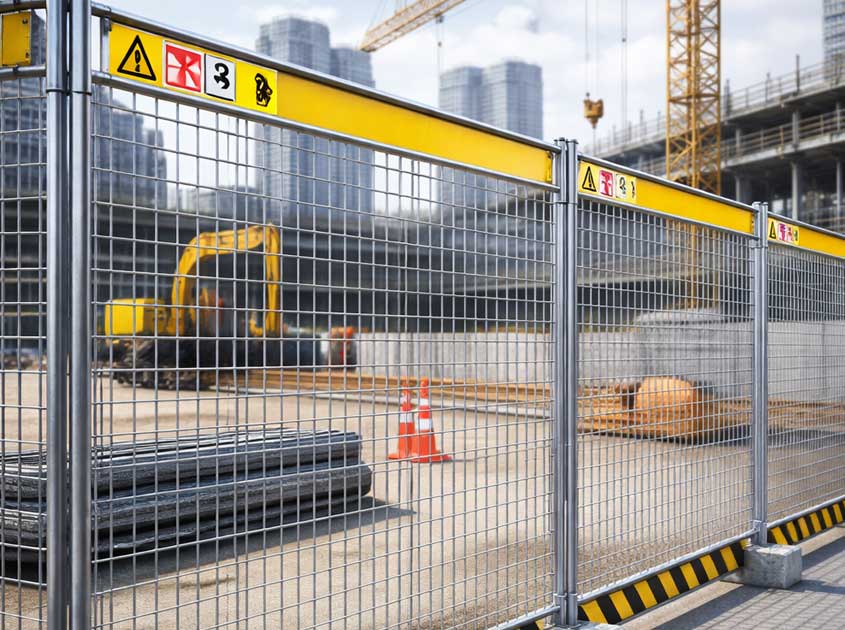

Fencing and security: Welded mesh, chain link fences, or expanded metal panels for residential, commercial, and agricultural projects.

Construction reinforcement: Reinforcing mesh for concrete, gabions, or masonry applications.

Industrial and filtration: Woven wire mesh for sieving, screening, or protective barriers in factories and processing plants.

Decorative and architectural applications: Decorative mesh panels, partitions, and façades for commercial and high-end residential projects.

Understanding end-use ensures you select the right mesh type, wire gauge, and panel size.

5. Evaluate Customization and OEM Options

Customization is increasingly important in South America, especially for architectural and industrial projects:

Custom panel sizes and mesh patterns to fit project specifications

Special coatings or materials for local environmental conditions

Private labeling or branded packaging for distributors and contractors

Working with an experienced Chinese manufacturer that supports OEM solutions allows you to meet local market preferences and stand out from competitors.

6. Plan for Efficient Shipping and Packaging

Import logistics play a significant role in total cost and product condition:

Optimize packaging: Roll or panel packing with protective wrapping and pallets reduces shipping damage.

Full container loads (FCL): Minimize per-unit shipping costs.

LCL shipments: For smaller orders, ensure proper moisture protection and labeling.

Consider lead time: Shipping from China to South America typically ranges from 25–45 days depending on port and logistics.

Proper planning ensures timely delivery and reduces potential import issues.

7. Consider Pricing and Total Cost of Ownership

While initial purchase price is important, South American buyers should consider total cost of ownership:

Material durability: Higher-quality stainless steel may have a higher upfront cost but longer lifespan.

Maintenance requirements: Coated mesh reduces rust and repair costs.

Shipping and customs fees: Efficient packing and container planning reduce costs.

Repeat orders and warranty: Reliable manufacturers can provide consistent quality and long-term support.

Evaluating total cost ensures sustainable profits and customer satisfaction.

8. Work with Experienced Manufacturers

Partnering with a manufacturer experienced in South American exports provides significant advantages:

Familiarity with local regulations and certifications

Expertise in environment-specific material selection

Capability to customize products and packaging

Support with export documentation and logistics

Experienced manufacturers can guide buyers through every step, from product selection to delivery, ensuring a smooth market entry.

Conclusion

Choosing wire mesh products for the South American market requires careful consideration of regional standards, environmental conditions, material selection, and logistics planning. Both standard and customized wire mesh solutions can be viable, depending on the target application and customer needs.

By partnering with a professional Chinese wire mesh manufacturer that understands South American market requirements, international buyers can ensure durable, compliant, and profitable products for construction, industrial, and decorative applications.

-

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China