Best Wire Mesh for Construction Use in the Middle East

The Middle East is known for its impressive construction projects and high architectural standards. From skyscrapers and luxury resorts to infrastructure developments, the region demands materials that are not only functional but also capable of withstanding extreme weather conditions. Among the essential construction materials, wire mesh plays a crucial role in providing security, strength, durability, and aesthetic appeal.

This article will explore the best wire mesh options for construction use in the Middle East, helping contractors, developers, and engineers make informed decisions when sourcing these products.

1. Why Wire Mesh is Essential in Middle Eastern Construction

Wire mesh is commonly used in construction for various applications, including:

Reinforcement: Used in concrete structures, foundations, and walls to improve strength.

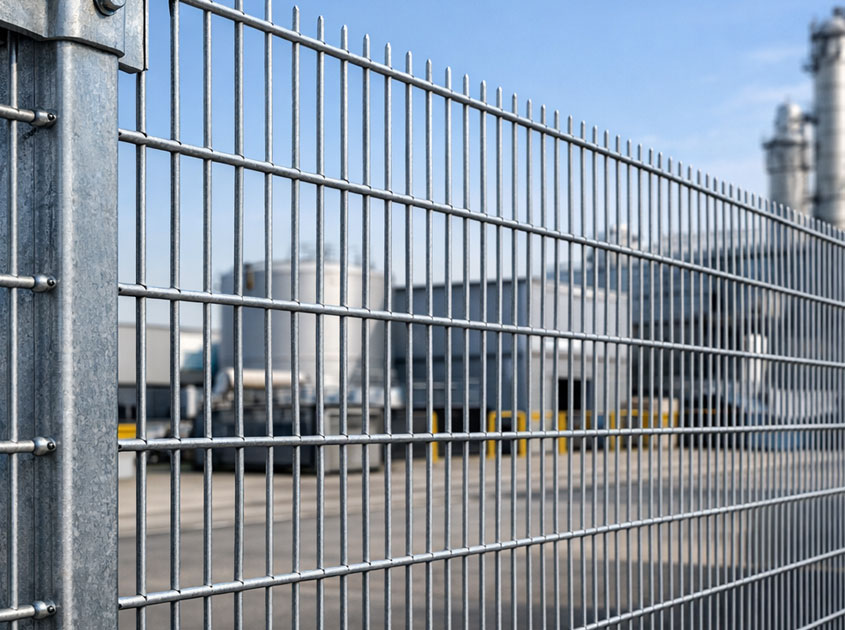

Security Fencing: Protecting sites from unauthorized access.

Facades and Architectural Features: Adding decorative and functional elements to buildings.

Industrial Applications: Screening, separation, and filtration.

Due to the harsh climate in the Middle East, including high temperatures, sandstorms, and saline air, selecting the right wire mesh product is critical for ensuring longevity and performance in construction projects.

2. Types of Wire Mesh Suitable for the Middle East Market

1. Hot-Dip Galvanized Welded Wire Mesh

Hot-dip galvanized welded wire mesh is one of the most popular choices for construction projects in the Middle East. The galvanization process involves coating the steel with a layer of zinc to prevent rust and corrosion, making it ideal for outdoor applications in harsh weather conditions.

Applications:

Reinforcement in concrete slabs, walls, and pavements.

Security fencing around construction sites, buildings, and residential areas.

Agricultural fencing for farms and ranches.

Benefits:

Corrosion resistance: Galvanized wire mesh is highly resistant to rust, even in humid or coastal environments.

High strength: Offers excellent structural integrity for reinforcement.

Long lifespan: The zinc coating ensures it lasts for decades.

2. PVC-Coated Wire Mesh

PVC-coated wire mesh is another excellent option for construction in the Middle East. The PVC coating adds an extra layer of protection to the wire mesh, making it more resistant to corrosion and damage from the elements. It also provides visual appeal with different color options, making it a popular choice for architectural applications.

Applications:

Fencing for residential, commercial, and industrial properties.

Landscaping and garden fences for aesthetic purposes.

Partitions and enclosures in buildings.

Benefits:

UV resistance: The PVC coating protects the wire mesh from the damaging effects of the sun, which is crucial in the Middle East's extreme heat.

Aesthetic appeal: Available in various colors such as green, black, and brown to blend with the surroundings.

Durability: Highly resistant to corrosion and environmental damage.

3. Stainless Steel Wire Mesh

Stainless steel wire mesh is one of the most durable and versatile materials used in construction. It is especially beneficial for projects that require superior strength and corrosion resistance.

Applications:

Reinforcement in high-strength concrete structures.

Filtration systems and separation processes in industrial applications.

Architectural facades, ceilings, and interior partitions.

Benefits:

Exceptional durability: Stainless steel is ideal for coastal areas where high humidity and saltwater can cause corrosion.

Fire resistance: Stainless steel does not burn or degrade, making it a safe option for high-rise buildings and industrial sites.

Aesthetic versatility: Can be used in decorative applications due to its sleek and modern appearance.

4. Chain Link Fencing

Chain link fencing is a traditional and cost-effective wire mesh solution widely used in the Middle East. It is commonly used for security purposes due to its strength and ease of installation. The chain link mesh is often galvanized or coated with PVC for extra durability.

Applications:

Perimeter fencing for construction sites, military installations, airports, and public spaces.

Temporary fencing during construction phases.

Security enclosures for sensitive areas.

Benefits:

Cost-effective: One of the most affordable wire mesh options for large areas.

Easy installation: Chain link fences can be quickly installed, making them suitable for fast-paced construction projects.

Maintenance: Requires minimal maintenance over time, particularly when galvanized or PVC-coated.

3. Key Considerations When Choosing Wire Mesh for the Middle East

1. Climate Resistance

The Middle East experiences extreme conditions, including intense heat, UV radiation, sandstorms, and salty coastal air. Therefore, choosing wire mesh products that are corrosion-resistant and capable of withstanding these challenges is essential. Galvanized and stainless steel mesh are the best choices for ensuring long-term durability.

2. Strength and Durability

Wire mesh used in construction needs to meet high standards of strength and load-bearing capacity, especially when it’s used for reinforcement or structural support in concrete projects. Materials like stainless steel and hot-dip galvanized mesh offer the necessary strength and longevity for demanding construction applications.

3. Customization Options

In large-scale construction projects, customized wire mesh solutions are often needed. Many projects in the Middle East require tailored mesh sizes, panel dimensions, and coatings to meet specific design and functional requirements. OEM customization from Chinese manufacturers can meet these needs at competitive prices.

4. Why Choose Chinese Wire Mesh Manufacturers for Middle Eastern Projects?

Chinese wire mesh manufacturers have become key suppliers for the Middle East market due to several advantages:

Cost-effectiveness: Chinese manufacturers offer wire mesh products at competitive prices compared to local suppliers.

Advanced manufacturing capabilities: Many Chinese factories have state-of-the-art equipment and technology for producing high-quality wire mesh that meets international standards.

Custom solutions: Chinese manufacturers can provide custom-designed wire mesh products to meet specific requirements for strength, size, and coating.

Efficient export logistics: With extensive experience in global exports, Chinese manufacturers are able to offer reliable shipping and delivery to the Middle East.

Conclusion

The best wire mesh products for construction use in the Middle East include:

Hot-dip galvanized welded wire mesh for reinforcement and security.

PVC-coated wire mesh for fencing and aesthetic applications.

Stainless steel wire mesh for high-strength and fire-resistant structures.

Chain link fencing for cost-effective perimeter security.

By choosing the right wire mesh solutions from trusted Chinese manufacturers, construction projects in the Middle East can benefit from durable, cost-effective, and high-quality materials that meet the demands of extreme environments.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China