Introduction:

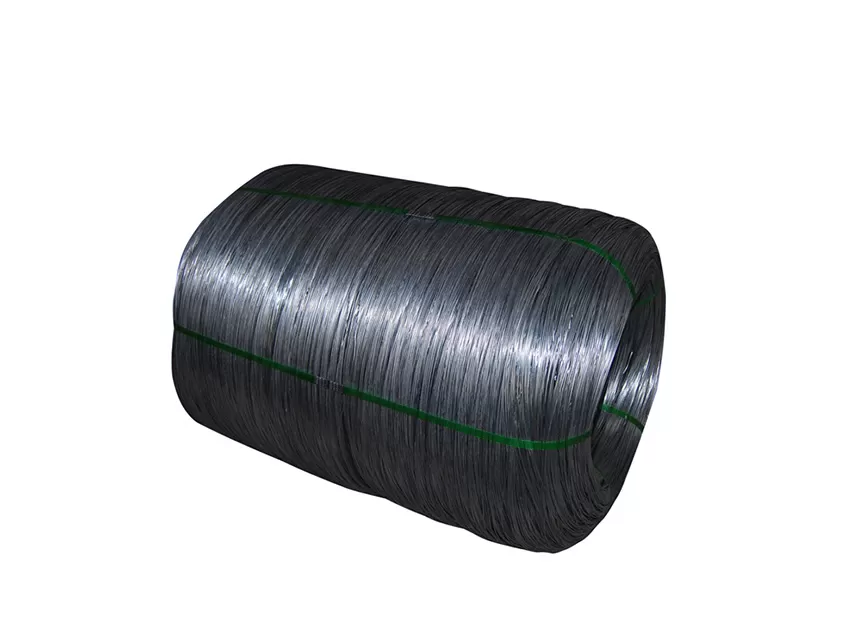

Black annealed wire is also called black iron wire, soft annealed wire, and annealed iron wire.

Black annealed wire is obtained by means of thermal annealing. It’s made of carbon steel wire.

Black annealed wire offers excellent flexibility and softness through the process of oxygen free annealing. And the black oiled wire is formed via the process of wire-drawing, anneal, and fuel oil injection. We can do it into straight cutting wire and also do it according to customers' special requirements.

Wire Materials: the main wire material of black annealed wire is iron wire or low carbon steel wire.

Black annealed wire is mainly used in construction, mining, chemical, etc.

Advantages of iron wire annealing: The wire elongation is increased after wire annealing. The product is softer and increases the applicable range of wire. Black annealed wire can be electro galvanized, hot-dip galvanizing, electroplating copper, etc., and it is widely used in wire mesh production. Post plating, first plating, etc.

Purpose of black annealed wire

● Black annealed wire is deployed both in construction and in agriculture. Hence, in civil construction black annealed wire, also known as ‘burnt wire’ is used for iron setting. In agriculture, annealed wire is used for bailing hay.

● Meantime black annealed wire is widely used as tie wire or baling wire in buildings, parks, and daily binding.

● It is used in the production of fences and other forms of wire mesh.

● Black annealed wire is mainly processed into coil wire, spool wire, big package wire or further straightened and cut into cut wire and U-type wire.

Features:

1. Flexibility.

2. Softness, the annealing process makes the wire soft and pliable.

3. Different diameters.

4. Different weights of coil or spool.

5. Different shape or length.

6. Corrosion Resistance: It has a certain level of resistance to corrosion due to the annealing process.

7. High Tensile Strength: Despite its softness, it retains good tensile strength.

8. Smooth Surface: The wire typically has a smooth surface finish.

Specifications:

| Wire Gauge Size | SWG(mm ) | BWG(mm) | BG(mm) |

| 6 | 4.87 | 5.15 | 5.032 |

| 7 | 4.47 | 4.57 | 4.481 |

| 8 | 4.06 | 4.19 | 3.988 |

| 9 | 3.66 | 3.76 | 3.551 |

| 10 | 3.25 | 3.40 | 3.175 |

| 11 | 2.95 | 3.05 | 2.827 |

| 12 | 2.64 | 2.77 | 2.517 |

| 13 | 2.34 | 2.41 | 2.24 |

| 14 | 2.03 | 2.11 | 1.994 |

| 15 | 1.83 | 1.83 | 1.775 |

| 16 | 1.63 | 1.65 | 1.588 |

| 17 | 1.42 | 1.47 | 1.412 |

| 18 | 1.22 | 1.25 | 1.257 |

| 19 | 1.02 | 1.07 | 1.118 |

| 20 | 0.91 | 0.89 | 0.996 |

| 21 | 0.81 | 0.813 | 0.887 |

| 22 | 0.71 | 0.711 | 0.749 |

| 23 | 0.61 | 0.025 | 0.707 |

| 24 | 0.56 | 0.022 | 0.629 |

| 25 | 0.51 | 0.02 | 0.56 |

| 26 | 0.46 | 0.018 | 0.498 |

Note: Special size and specifications can be made according to customers requires.

Technology:

Diameter: 0.3mm- 6.0mm

Tensile Strength: 33-50kg/mm2

Elongation: 10%-25%

Weight: 1kg-800kg/coil

Packaging: Inside with plastic film and outside with hessian

We offer high-quality black annealed wire, perfect for a wide range of applications in industries such as construction, agriculture, and manufacturing. Whether you need wire for binding rebar, creating trellises, or packaging, our black annealed wire is an affordable and reliable solution.

What is black anneal?

Black anneal refers to a heat treatment process applied to steel wire or other types of metal, in which the metal is heated to a specific temperature and then slowly cooled, resulting in a blackened, oxidized surface. This process is commonly used to improve the wire's ductility (ability to bend without breaking), flexibility, and workability, making it easier to manipulate, twist, or form into various shapes. The term "black anneal" specifically refers to the wire or metal having a dark, matte finish due to the oxidation layer formed during the annealing process.

Product Name: Black Annealed Wire