Your Quick Guide to Buying Perforated Metal Mesh

Perforated metal mesh is a versatile material used in a wide range of applications, from construction and industrial design to architectural aesthetics and filtration. Whether you’re building a custom project or working on a large-scale industrial application, choosing the right perforated metal mesh is essential for performance, durability, and aesthetics. In this guide, we will walk you through the key factors to consider when buying perforated metal mesh.

1. Understand Your Requirements

Before purchasing perforated metal mesh, it's important to clearly define your specific needs. Consider the following factors:

Application: What will the mesh be used for? Is it for decorative purposes, industrial filtration, ventilation, or security? Knowing the application helps determine the necessary hole size, material, and durability requirements.

Size and Dimensions: Determine the size of the perforated sheet you need. Measure the area where the mesh will be installed or used, and decide whether you need a custom size or a standard sheet.

Load and Pressure: Consider the load-bearing and pressure requirements. For applications like industrial filters or security fencing, you'll need a stronger material with appropriate thickness and hole size.

2. Material Selection

Perforated metal mesh is available in various materials, each with its unique properties. Here are the most common options:

Stainless Steel: Stainless steel perforated metal is highly resistant to corrosion and is ideal for outdoor applications or environments where moisture and rust are concerns. It is commonly used in filtration, food processing, and architectural designs.

Aluminum: Aluminum is lightweight, corrosion-resistant, and offers good strength. It is often used in decorative applications and lightweight industrial uses. It is also easier to work with than stainless steel.

Carbon Steel: Carbon steel is stronger than aluminum but more prone to rust. It is often used in applications where strength is needed, and where the mesh will be coated or treated to prevent rust.

Galvanized Steel: Galvanized steel is steel that has been coated with a layer of zinc to prevent rust. It is commonly used in construction, agricultural, and automotive industries.

3. Hole Pattern and Size

The hole pattern and size are crucial factors to consider when selecting perforated metal mesh. The most common patterns include:

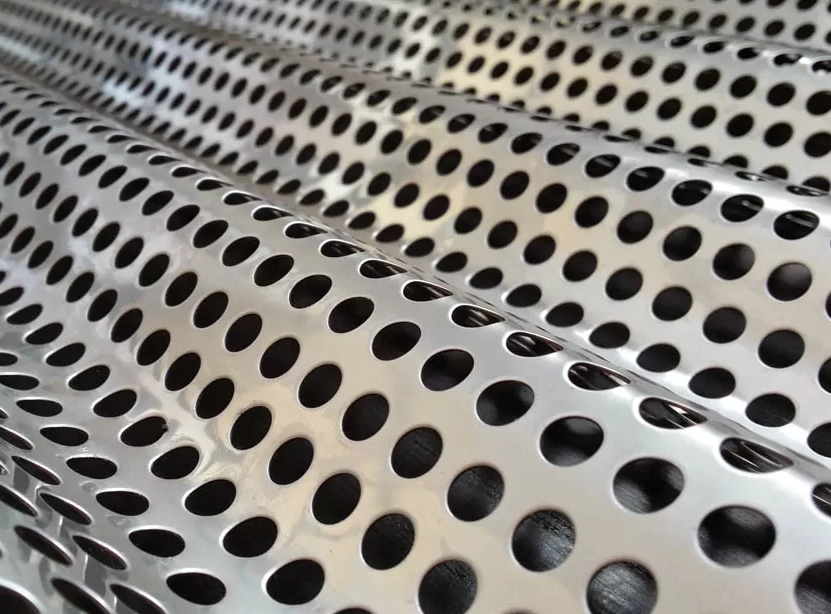

Round Holes: These are the most popular and versatile, offering good strength and uniformity. They are used in a variety of applications, from ventilation systems to decorative facades.

Square and Rectangular Holes: Square or rectangular holes provide more space and are often chosen for filtration or applications requiring higher airflow or material passage.

Slot Holes: Slot holes are ideal for applications requiring drainage or for use as grates or covers in flooring, walkways, and other surfaces.

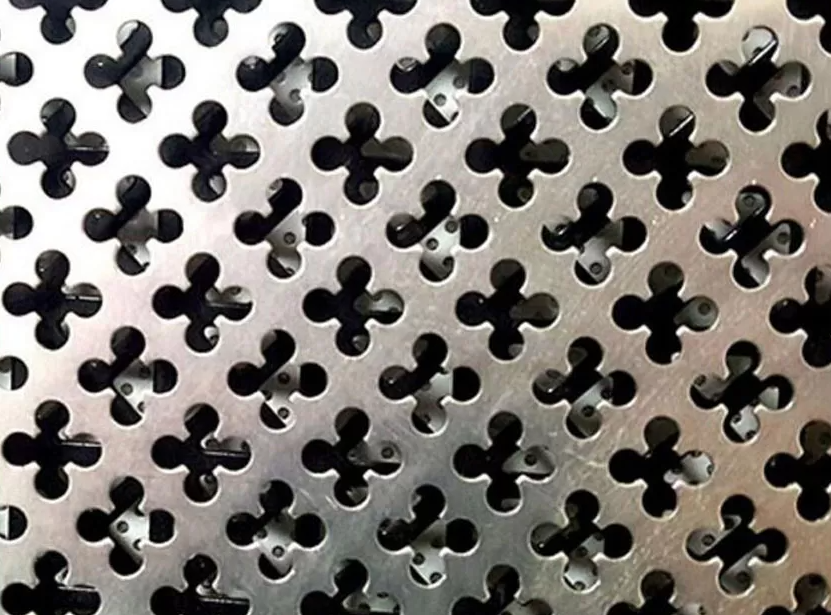

Custom Patterns: Depending on your application, you may need a custom hole pattern. Manufacturers often offer bespoke solutions for unique designs or performance needs.

The size of the holes affects the strength of the mesh. Smaller holes typically result in stronger, more rigid material, while larger holes create more space for airflow or material passage but can reduce the mesh’s structural integrity.

4. Thickness and Gauge

The thickness of the perforated sheet will determine its strength, durability, and overall weight. Thicker sheets offer more structural integrity but may be more difficult to work with. The gauge (or thickness) of the metal will also impact its ability to withstand pressure, weight, and environmental stress.

Light Gauge (0.5mm to 1.5mm): Ideal for applications like decoration, protection, or lightweight filtration systems.

Medium Gauge (2mm to 3mm): Suitable for more demanding industrial and structural applications.

Heavy Gauge (4mm and above): Best for applications requiring high strength, like security barriers, grilles, and structural supports.

5. Finishes and Coatings

In many cases, perforated metal mesh will require a protective coating or finish to enhance its durability, appearance, and resistance to corrosion. Common finishes include:

Powder Coating: Provides a smooth, durable, and long-lasting finish. Ideal for decorative and outdoor applications.

Anodizing: A finish for aluminum mesh that creates a hard, corrosion-resistant layer. Common in architectural applications.

Galvanization: A coating of zinc applied to steel to protect against rust and corrosion. Often used for outdoor and industrial applications.

Polished or Brushed Finishes: These finishes give the mesh a smooth, aesthetic appearance and are commonly used in interior design.

6. Strength and Durability Considerations

The strength and durability of perforated metal mesh depend on a combination of the material, thickness, and hole size. For heavy-duty applications, such as security fencing or industrial filtration, you may need mesh with a thicker gauge and smaller holes to ensure it can withstand heavy loads, high pressure, or environmental stress. For decorative purposes or lightweight applications, thinner gauges and larger holes may be sufficient.

7. Cost and Budget

The cost of perforated metal mesh can vary significantly based on the material, thickness, hole pattern, size, and finish. It’s important to balance the features you need with your budget. Stainless steel and custom hole patterns are usually more expensive than aluminum or standard round hole mesh. Keep in mind that while the upfront cost may be higher for durable materials, it may save money in the long run by reducing the need for frequent replacements or repairs.

8. Supplier Reputation and Quality Assurance

When purchasing perforated metal mesh, it’s crucial to choose a reputable supplier. Look for suppliers with a history of providing high-quality products and good customer service. Additionally, ask about their quality assurance processes and certifications to ensure you’re getting durable and reliable materials. Check for customer reviews, product samples, or case studies to gauge the supplier’s reliability and quality.

9. Customization Options

If your application requires specific sizes, patterns, or finishes, many suppliers offer customization options. Custom perforated metal sheets are perfect for unique projects where standard sizes or patterns won’t meet your needs. Ensure that the supplier can provide the necessary customization and that the price fits within your budget. Be clear about your specifications to ensure the final product matches your requirements.

10. Sustainability Considerations

If sustainability is important to you or your company, consider the environmental impact of the perforated metal mesh you’re purchasing. Materials like stainless steel and aluminum are highly recyclable, making them a more eco-friendly choice. Also, check if the supplier has sustainable practices in place, such as reducing waste during production or using recycled materials.

Conclusion

Buying perforated metal mesh requires careful consideration of factors such as material, hole size, gauge, finish, and your specific application. Whether you need perforated mesh for decoration, filtration, or industrial purposes, understanding these key elements will help you choose the right product for your needs. By considering your specific requirements, working within your budget, and selecting a trusted supplier, you can ensure that you’re getting a high-quality perforated metal mesh that meets both functional and aesthetic demands.

Where can I buy perforated metal mesh?

Our team at QUNKUN METAL can help! Contact us with your questions! Shop for perforated steel sheet at QUNKUN METAL. Largest selection of steel perforated at wholesale prices.

-

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China