This article introduces the detailed process of making hexagonal wire mesh

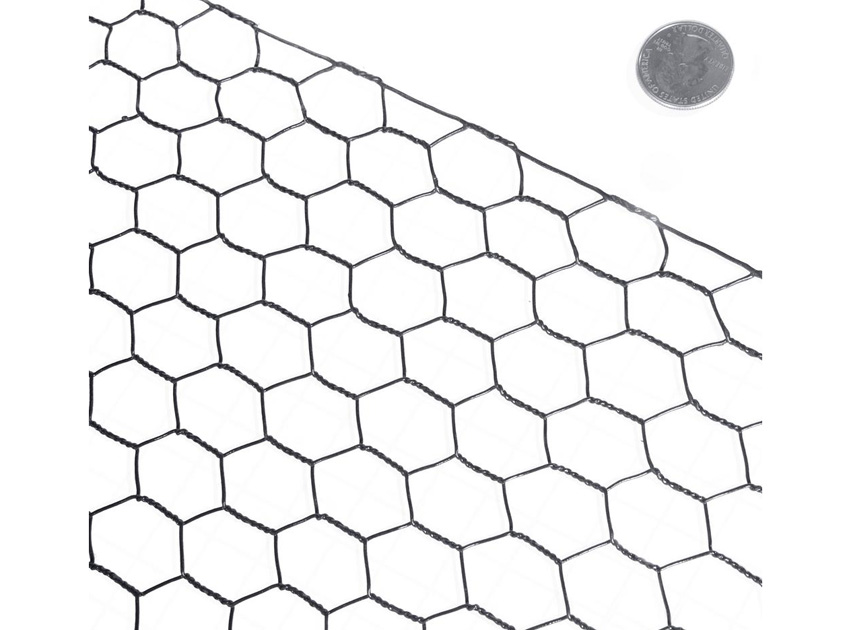

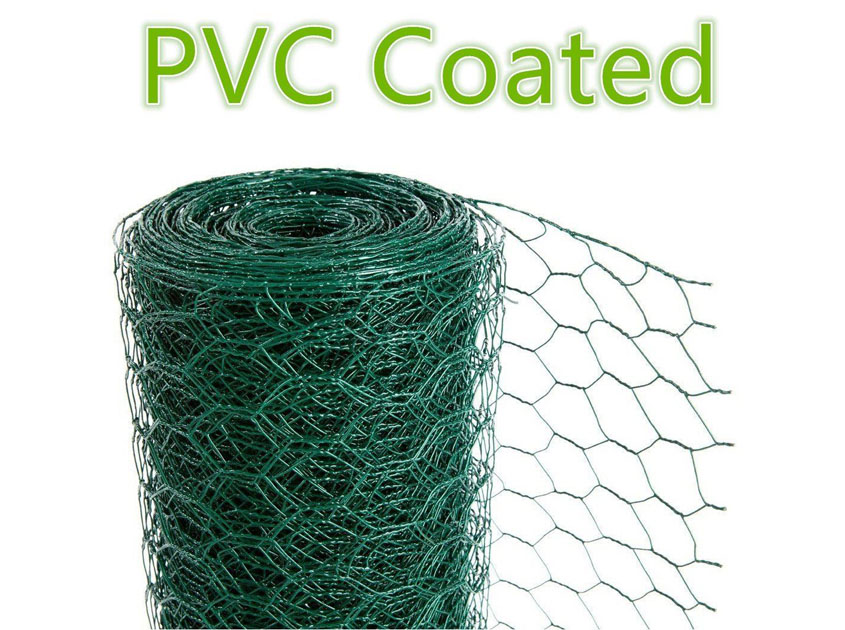

Hexagonal wire mesh is a popular type of wire mesh that is commonly used in various industries, such as agriculture, construction, and gardening. It is made from high-quality galvanized wire, which is woven into a hexagonal shape. The following is a detailed process of how hexagonal wire mesh is made:

Wire Drawing: The first step in making hexagonal wire mesh is to draw the wire. The galvanized wire is fed through a series of dies to reduce its diameter to the required size.

Annealing: After the wire is drawn, it is annealed to improve its ductility and reduce its hardness. This process involves heating the wire to a high temperature and then cooling it slowly.

Weaving: The next step is to weave the wire into a hexagonal shape. The weaving process involves passing the wire through a series of rollers and then through a weaving machine, where the wire is woven into a hexagonal shape.

Galvanizing: Once the wire mesh is woven, it is galvanized to protect it from rust and corrosion. The galvanizing process involves dipping the wire mesh into a bath of molten zinc, which forms a protective coating on the surface of the wire mesh.

Cutting and Shaping: After the wire mesh is galvanized, it is cut and shaped to the required size and shape. This is done using a wire mesh cutting machine, which cuts the wire mesh into the desired shape and size.

In conclusion, hexagonal wire mesh is made through a series of processes, including wire drawing, annealing, weaving, galvanizing, and cutting and shaping. The final product is a durable and versatile wire mesh that can be used in a variety of applications, including agriculture, construction, and gardening.

-

Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China