How to Ensure Reliable Technical Support and After-Sales Service When Purchasing Wire Mesh Products

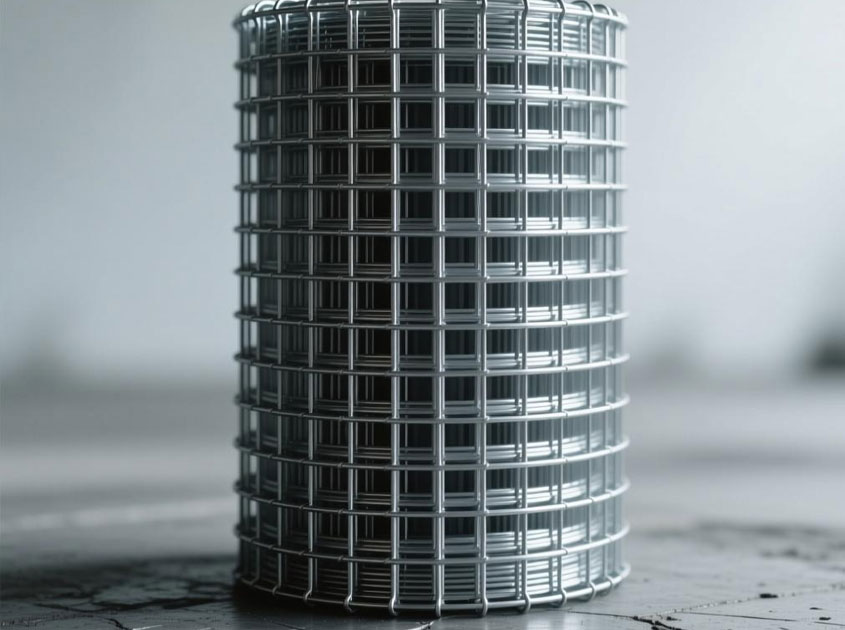

For B2B buyers in construction, agriculture, security fencing, and industrial filtration, purchasing wire mesh products is not only about comparing prices. What truly influences long-term cooperation is the supplier’s technical support, quality assurance, and after-sales service. Whether you are importing galvanized wire mesh, welded mesh rolls, chain link fence, or decorative metal mesh from overseas manufacturers, choosing the right supplier determines how efficiently your projects run.

Below is a practical guide to help international distributors, contractors, and wholesalers ensure solid technical support and reliable after-sales service when working with wire mesh suppliers—especially when sourcing from China.

1. Start by Evaluating the Supplier’s Technical Expertise

Before placing an order, verify whether the manufacturer can provide professional technical guidance. This is particularly important for projects that require accurate mesh specifications, tensile strength, corrosion resistance, or special coatings.

You should check:

Production experience (years in manufacturing, main markets served)

Technical team availability (engineers, QC specialists, customization support)

Material understanding (galvanized wire, stainless steel, PVC-coated wire, etc.)

Standards compliance (ISO, CE, SGS test reports)

Professional manufacturers usually provide:

Mesh size recommendations

Load-bearing calculations

Installation guidelines

Application-specific solutions

This ensures that the wire mesh you purchase matches your market requirements, reducing risk and improving procurement accuracy.

2. Ensure Clear and Transparent Pre-Sales Communication

Reliable technical support begins before the purchase. You should expect quick and detailed responses to technical questions, including:

Product drawings

Exact specifications and tolerances

Sample confirmation

Customization feasibility

Estimated delivery timelines

A qualified supplier will proactively ask about your application scenario (fencing, construction reinforcement, animal breeding, industrial filtration, decoration, etc.) to offer the most suitable mesh type, instead of simply selling what’s in stock.

For overseas buyers, clear communication is essential to avoid misunderstandings in mesh aperture, wire diameter, length, roll size, and zinc coating thickness.

3. Request Full Quality Control Documentation

A supplier’s after-sales capability strongly depends on its production and inspection system.

Before confirming a large order, ask for:

Raw material certificates

In-process QC photos

Finished product inspection reports

Tensile strength tests

Coating thickness tests

Packaging inspection photos

These documents give you confidence that the factory has:

Strict quality control

Traceable production records

Stable and consistent output

Lower risk of complaint or product failure

Factories with complete QC data are more likely to provide solid after-sales service, because they can track any issue back to production.

4. Understand the Supplier’s Warranty and Claim Policy

When purchasing wire mesh, after-sales service includes:

Quality warranty period

Replacement policy for defective products

Compensation mechanism

Technical troubleshooting support

Make sure the supplier clearly states:

What conditions are covered

How claims are handled

Response time for technical issues

Whether replacements or discounts are offered

Professional manufacturers will provide a written after-sales guarantee, giving distributors confidence when reselling products to their own clients.

5. Pay Attention to Packaging, Shipping, and Damage Prevention

A large portion of after-sales issues worldwide comes from transportation damage, especially for:

Welded wire mesh rolls

Stainless steel mesh

Chain link fence

Expanded metal and decorative mesh panels

To avoid disputes, confirm that the supplier uses:

Waterproof wrapping

Steel pallets

Strapping and protective edges

Clear labeling

A factory that invests in export-grade packaging usually takes after-sales service seriously, because good packaging directly reduces damage claims.

6. Check Whether the Supplier Provides Installation and Usage Support

For many projects, technical support continues after delivery.

Reliable wire mesh manufacturers provide:

Installation manuals

Video guidance

On-site technical advice (if needed)

Online troubleshooting

Long-term product maintenance suggestions

This is especially useful for:

Security fencing systems

Architectural decorative mesh

Industrial filter mesh

Agricultural and breeding mesh

Proper installation not only extends product lifespan but also protects the buyer’s reputation in local markets.

7. Choose Suppliers With Stable Long-Term Service Capability

For distributors in South America, the Middle East, Europe, and Southeast Asia, working with a stable Chinese manufacturer ensures consistent after-sales support.

Reliable suppliers typically have:

A large production base

Continuous R&D investment

Export-oriented service teams

Strong logistics networks

Long-term cooperation with distributors

These manufacturers can provide ongoing technical support, new product recommendations, and tailored solutions—reducing your operational costs and improving market competitiveness.

Conclusion

Buying wire mesh products is more than just comparing prices—it is about choosing a supplier who can guarantee quality, technical support, and long-term after-sales service. By evaluating expertise, documentation, communication, warranty policies, packaging, and installation support, distributors and project contractors can avoid risks and secure stable, profitable supply partnerships.

If you are sourcing from China, collaborating with an experienced wire mesh manufacturer ensures that your purchase is supported before, during, and after the sale—helping your business grow with confidence.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China