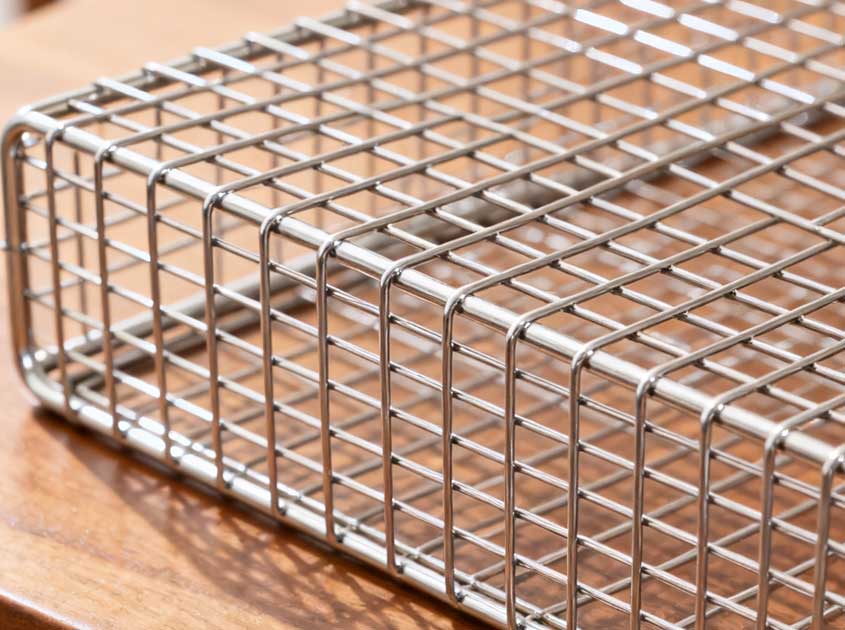

Corrosion-Resistant Stainless Steel Wire Mesh

Stainless steel wire mesh is widely used in industrial, architectural, and agricultural applications due to its corrosion resistance and long service life. Understanding the corrosion protection processes can help B2B buyers select the right products for demanding environments.

Corrosion Protection Techniques

Electroplating

Stainless steel wires can be coated with zinc or nickel to enhance surface corrosion resistance. Electroplating provides a uniform protective layer, suitable for humid or saline environments.

Passivation Treatment

Passivation involves removing free iron from the surface to form a protective oxide layer. This increases the wire mesh’s resistance to rust and chemical exposure.

Galvanization

Hot-dip galvanizing involves immersing stainless steel wire in molten zinc, creating a thick, durable anti-corrosion coating. This method is effective for outdoor and marine environments.

Powder Coating

For aesthetic applications or added chemical resistance, stainless steel wire mesh can be coated with powder paint. It enhances durability and allows color customization.

Applications

Industrial filtration

Architectural facades and interiors

Food processing and hygiene facilities

Outdoor fencing and protective screens

Benefits for Buyers

Long lifespan reduces replacement costs

Enhanced performance in harsh environments

Compliance with international quality standards

Customizable solutions for specific applications

Conclusion & CTA

Investing in corrosion-resistant stainless steel wire mesh ensures reliability, performance, and long-term value. Request a quote today for tailored corrosion-resistant wire mesh solutions.

-

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China