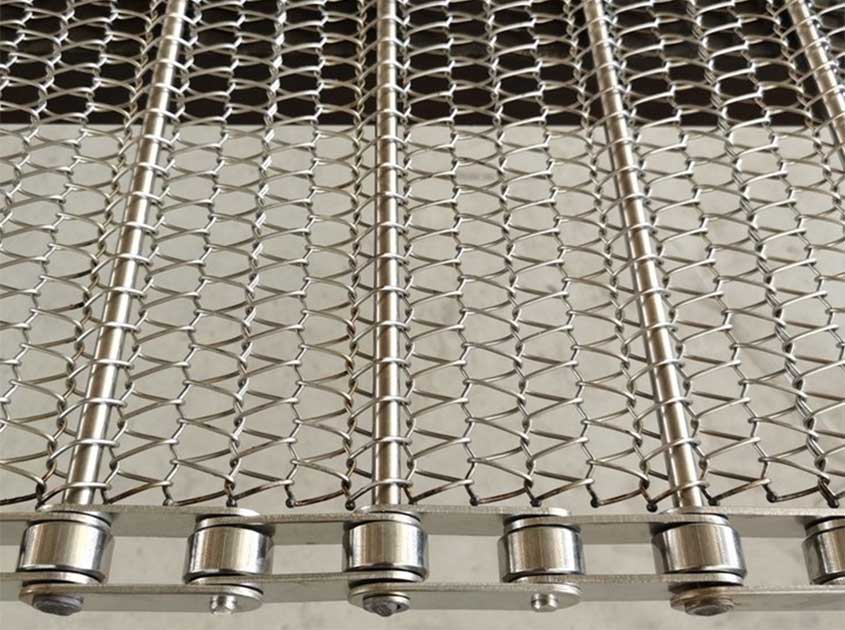

The common Chain type conveyor belt

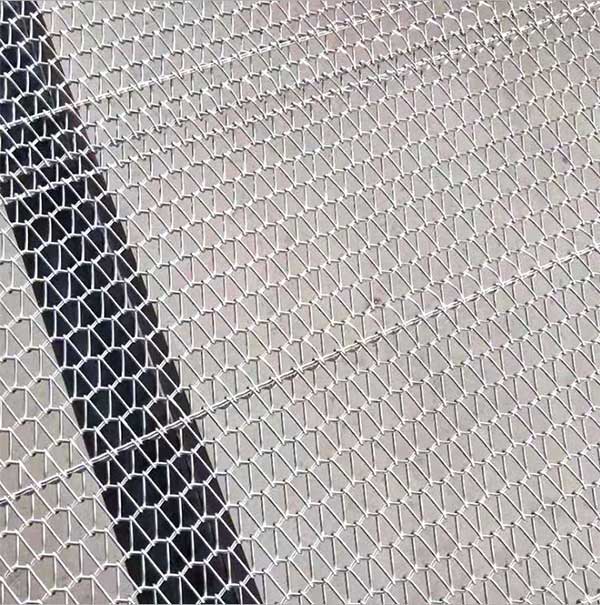

Chain type conveyor mesh belt is popluar in world. It is mainly composed of chains with various specifications on both sides, and a connecting rod is installed in the middle to strengthen the overall load capacity of the conveyor belt. According to different conveying requirements, the middle installation is added. Various forms of spiral metal conveyor belts, connecting chain hooks, connecting punching sheets, chain plates, etc., can achieve good carrying and conveying effects.

Usually, its operating temperature: -40℃~1200℃, and have many types on edge, it has bending, heading, welding and other forms.

The mesh belt material has the SUS304, 314, 316, NI-CR 2080, Low carton steel and so on.

This kind belt is with roller chain and without roller chain as the customer’s request.

The more commonly used roller chain models are as follows: 06B, 08B, 10A, 12A, 16A, 20A, 24A, C2040, C2042, C2050, C2052, C2060, C2062, C2080, C2082, and some non-standard chains with P=50mm and P=100mm .

The chain mesh belt can effectively prevent the conveyor belt from deviating, and can control the tension and conveying speed according to the configured chain. It has been well used in food, pharmaceutical machinery and other mechanical products that require precision conveying, its characteristics has good corrosion resistance, wear resistance, high temperature resistance and other properties, and has satisfactory anti-cold shrinkage, anti-oxidation and anti-fracture properties at low temperature and high temperature.

-

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China