Steel Grating: Complete Guide to FAQs

Steel grating is an essential material widely used in various industries such as construction, manufacturing, and infrastructure. It is valued for its strength, durability, and versatility. However, many people have questions regarding its features, uses, and installation. In this article, we provide answers to frequently asked questions about steel grating, addressing the common concerns and helping you understand its importance in different applications.

What is Steel Grating?

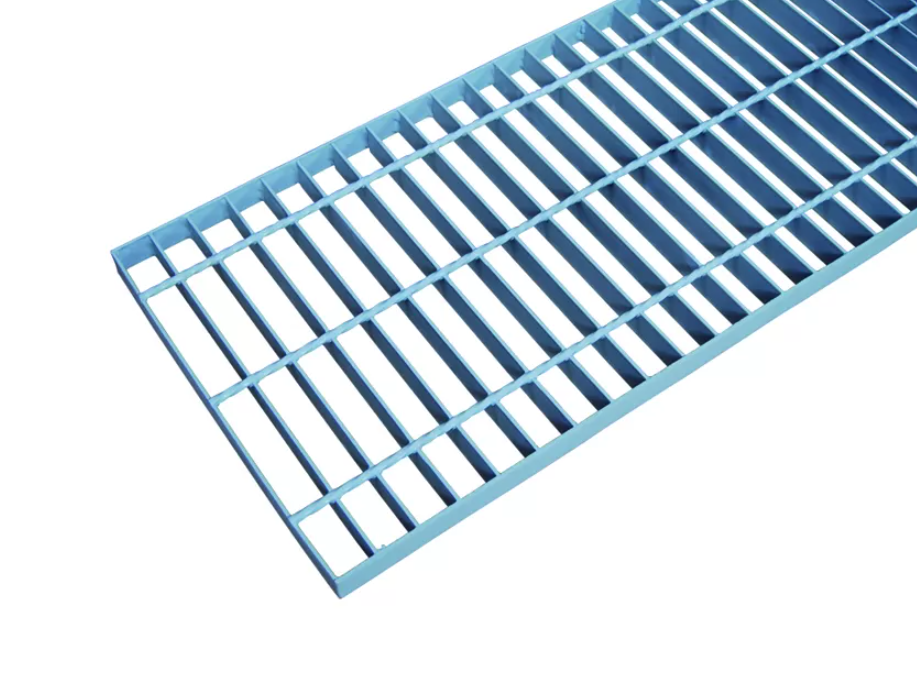

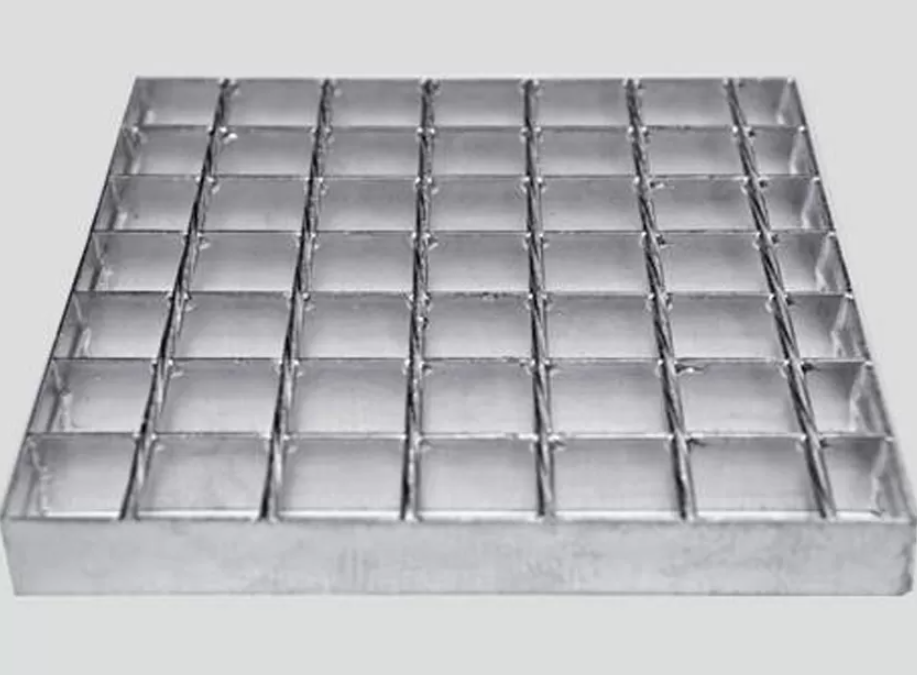

Steel grating is a type of metal flooring or covering made from steel bars arranged in a series of parallel lines, usually with open spaces between them. It is commonly used in walkways, platforms, and industrial floors, offering both strength and safety. Steel grating comes in various types, including welded, press-locked, and swaged, each with its unique applications depending on the requirements of the project.

What are the Benefits of Steel Grating?

Steel grating offers numerous benefits, making it a popular choice in industrial and commercial settings. Some of its key advantages include:

Strength and Durability: Steel grating is known for its exceptional strength, capable of withstanding heavy loads, making it suitable for high-traffic areas.

Safety: The open spaces between the bars allow water, debris, and other materials to pass through, reducing the risk of accidents and slips.

Low Maintenance: Steel grating is easy to clean and maintain, requiring minimal effort to preserve its functionality.

Corrosion Resistance: Many steel grating options are coated with anti-corrosion treatments, ensuring longevity even in harsh environmental conditions.

How is Steel Grating Manufactured?

Steel grating is manufactured using several techniques, including welding, press-locking, and swaging. These methods involve creating a grid-like structure by securing steel bars at specified intervals, ensuring the product's durability and strength. Depending on the manufacturing process, different types of steel grating can be produced, each suited for specific applications:

Welded Steel Grating: Bars are welded at intersections to form a solid and sturdy structure.

Press-Locked Steel Grating: Bars are interlocked under pressure without welding, offering a lighter, cost-effective alternative.

Swaged Steel Grating: Bars are inserted into pre-punched holes and swaged into place, providing a smooth surface for various applications.

Where is Steel Grating Used?

Steel grating is used in various industries, including:

Construction: For walkways, stair treads, and drainage covers, providing safe, slip-resistant surfaces.

Manufacturing: For heavy-duty flooring, platforms, and mezzanines in factories and warehouses.

Oil & Gas: For offshore platforms, refineries, and pipelines, offering corrosion-resistant solutions in harsh environments.

Transportation: For bridges, train stations, and bus terminals, where durability and safety are critical.

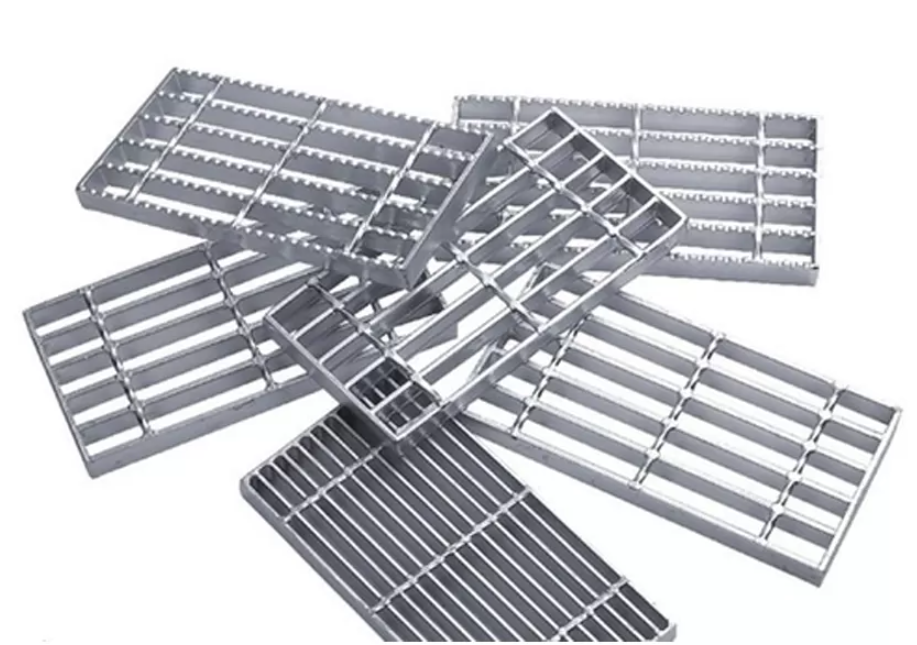

What Are the Different Types of Steel Grating?

Steel grating comes in several types, including:

Welded Grating: Offers a strong, secure, and uniform surface ideal for heavy-duty industrial applications.

Swaged Grating: Known for its smooth surface, often used in areas requiring a clean aesthetic or where foot traffic is frequent.

Press-Locked Grating: A more economical choice, commonly used for general-purpose applications where strength is still required.

Stainless Steel Grating: Offers higher resistance to corrosion and is suitable for environments exposed to chemicals or extreme weather conditions.

How Do You Install Steel Grating?

Installing steel grating involves the following steps:

Preparation: Ensure that the surface where the grating will be installed is clean, level, and ready for installation.

Measuring and Cutting: Measure the required dimensions for the grating and cut the material to fit the designated area if necessary.

Positioning: Place the grating onto the surface, ensuring that it fits securely and aligns properly.

Securing: Fasten the grating using bolts, clips, or welding, depending on the type and location of installation.

Is Steel Grating Expensive?

The cost of steel grating depends on several factors, including the material type (mild steel, stainless steel, etc.), the manufacturing process, and the size or customizations required. While steel grating may initially seem costly, its long lifespan, low maintenance, and high durability make it a cost-effective solution over time. Additionally, opting for different types (such as press-locked or swaged) can provide more budget-friendly options while still meeting performance standards.

Steel Grating vs. Other Grating Types: What’s the Difference?

When comparing steel grating to other types of grating, such as aluminum or fiberglass, the main differences lie in strength, durability, and environmental suitability. Steel grating tends to be the strongest, offering greater load-bearing capacity, while aluminum grating is lighter and resistant to corrosion but may not support as much weight. Fiberglass grating, on the other hand, is non-conductive and offers a more flexible installation process but lacks the strength and load-bearing capacity of steel. Choosing the right type depends on the specific requirements of the project, including safety, durability, and environmental conditions.

FAQ Section

What is the load-bearing capacity of steel grating?

The load-bearing capacity of steel grating depends on the type of grating and its design, such as the spacing between bars and the material used. Typically, steel grating can support heavy loads, ranging from 500 lbs to several tons per square foot, depending on these factors.

Can steel grating be used in outdoor environments?

Yes, steel grating is commonly used in outdoor applications due to its strength and resistance to various environmental conditions. Some types of steel grating are coated with anti-corrosion materials to ensure they remain durable even in harsh climates.

How do I clean steel grating?

Cleaning steel grating is easy and can be done using a pressure washer or a broom to remove debris. For more stubborn dirt, a cleaning solution with mild detergent may be used to ensure the grating remains clear of any buildup that could reduce its effectiveness.

By understanding the various aspects of steel grating, including its uses, benefits, and installation process, you can make informed decisions when considering this material for your next project. Whether it's for a commercial, industrial, or construction application, steel grating proves to be an indispensable and reliable solution.

When strength, safety and weight are critical, QUNKUN METAL has the grating solution for you. Grating is commonly used in platform, mezzanine, flooring, walkway, and trench applications The vast majority of the grating we carry can also be made into stair treads. Our customers also choose grating for vertical applications such as partitions, fences, and infill panels.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China