Process and effect of dust-proof net

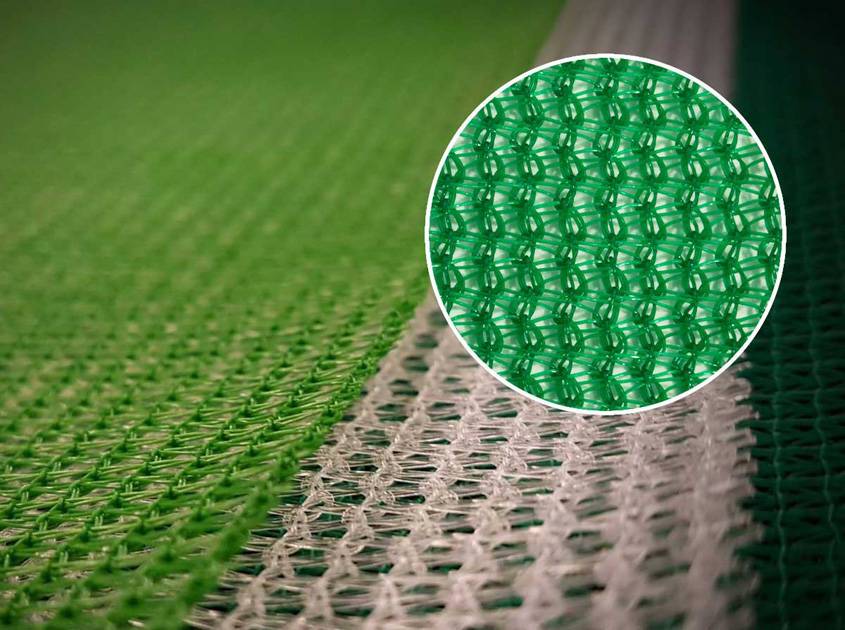

The greening net is made of metal raw materials through a series of processes through mechanical molds. Due to the good quality of the raw materials, the fabricated soil covering net has many advantages: good flexibility, high tensile strength, high temperature resistance, ultraviolet radiation resistance, and corrosion resistance. It can also be made into finished products with different thicknesses and colors through different processing techniques and adding different ingredients to meet the different needs of users. Instead of the old process, the color is changed by spraying paint on the surface, which needs to be carried out in a tightly closed space, which is demanding, expensive and easy to fade. On the contrary, the new technology has achieved the effects of long service life, non-fading, and flame retardant.

How does the dust-proof net achieve the effect of dust prevention? According to the relevant tests, the dust-proof net is made into a barrier, and the wind direction parallel to the barrier is made on one side of the barrier, which will cause the flow of air up and down to change the wind force. The size, many times of testing, one side has weak wind, strong wind blowing, the other side blocked by the dust-proof net barrier is not affected or has little impact. If in actual use, there is wind in the upper part of the dust-proof net, but no wind in the lower part, the dust in the lower part covered by the dust-proof net can avoid generating dust, thus achieving the effect of dust prevention.

In actual use, if you want to increase the dust-proof effect, you can also choose to use two or more layers of dust-proof nets to achieve a smaller mesh density for blocking, but you need to consider the nature of the covering. Some uncovered materials require a certain amount of air exchange, such as plants, so they should be considered comprehensively.

-

Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China