Guide: How to choose stainless steel filter products

In the process of purchasing a stainless steel filter screen, determine the number of meshes: the one-inch long mesh, the thickness of all warp and weft wires woven in the vertical and horizontal direction of the stainless steel filter screen, and the determination of the mesh size: between two warp threads or two weft threads The distance Diameter is the diameter of the wire. Confirm the mesh density (unit: g/cm3 or kg/m3): the number of meshes within one centimeter of length.

The service life of ordinary stainless steel mesh belts is shorter than stainless steel mesh belts, because our use environment is very complicated, such as high temperature, corrosion and other environments. As we all know, stainless steel mesh belts are characterized by high temperature resistance, corrosion resistance and high strength.

304 stainless steel wire mesh applicable industries: widely used in the filtration of melts such as "chemical fiber spinning, short fiber, superfine fiber, leather, non-woven fabric, plastic granulation, sheet extrusion, color masterbatch, rubber" and so on.

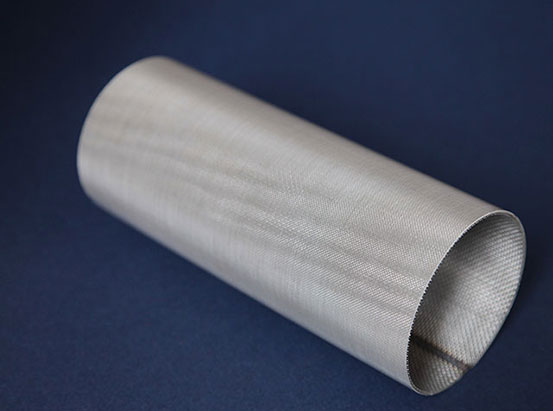

Uses of stainless steel filter screen: used for screening and filtering under acid-base environmental conditions, as a slurry screen in the petroleum industry, as a screen filter in the chemical fiber industry, and as a pickling screen in the electroplating industry. The filtration effect of the diamond mesh is very stable: high-quality raw materials are used in the production process, and it is not easy to deform during use; high strength: high-quality materials have higher pressure resistance and can withstand greater working strength. Also note that the surface of the stainless steel filter must not have any unqualified phenomena such as delamination, scarring, pull marks, folding (meaning: part of a folded object), concave surface, rust, pitting, slub, oxidized color, etc.: it is the surface Partial or often longitudinal cracks, yellow-white oxidized scars, and obvious small grooves, ridges, and depressions make the surface look matte and shiny. The surface should not have spot or flake pits that appear during the partial and overall oxidation process. The periodic uneven thickness during the correction process makes the surface unsightly and looks like bamboo joints.

The above introduction is a summary of the matters that should be paid attention to when purchasing stainless steel filter products. I hope it will be helpful to all buyers.

-

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China