Filter Disc: The Ultimate Guide

The filter disc can avoid expensive system shutdown due to clogging. Yes, allowing impurities in the system can be a disaster. In fact, it may cause system failure. Therefore, you should invest in high-quality, high-reliability filter discs.

Today’s guide will take you through the key aspects of filters, including basic definitions, structure, types, and application advantages. It will help you choose the right accessories to meet your unique needs.

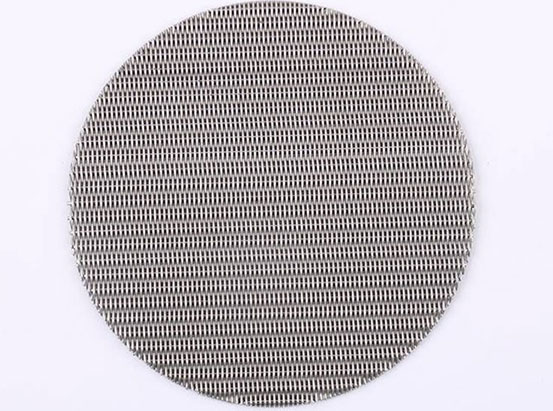

Definition of filter disc A filter disc is a filter that can be used to filter different fluids, especially irrigation water.

The filter element of the filter disc is made up of different filter discs stacked on top of each other, and all the filter discs have small ridges or grooves, which may confuse a pile of filter discs into a pile of poker chips. The center of a hollow cylinder is formed in the middle, which will provide a channel for water to pass through when the disc blocks impurities.

Under normal circumstances, the quality of filtration depends on the size and quantity of the filter element that can be retained. The color code of the filter disc here indicates the filtration level. The micron level of most filter discs ranges from 20 microns to very fine filtration levels. It can be extended to 400 microns for rough filtration. You may also find other filter discs that use mesh size to measure filter quality.

Generally, the size of the mesh is in the range of 40 micrometers to 600 micrometers. In this case, the thickest is 40 microns and the thinnest is 600 microns. Different types of filter discs The size of the filter discs varies from ¾ inch to 3/4 inch. The smallest entrance and exit. The size will also vary depending on the application. Small filter discs are mainly used for drip irrigation systems, while larger filter discs are used for large industrial applications. After understanding what a filter disc is, let us take a look at some of the advantages of the filter disc.

Advantages of using a filter disc Using a filter disc has many advantages. Compared with filter media, the filter disc can backflush faster and more effectively. Some of the benefits of disc filters include: the maintenance of the filter disc is very easy to maintain, and you will also spend very little time to disassemble and clean the filter disc. In addition, installation and replacement are very quick and easy, and you may not need a technician. Additional services to help you maintain. Just follow the manufacturer's manual and everything will be in place. ·Low pressure consumption According to the application, the filter disc will not run under high pressure. This means that the system may not need a power supply system to increase the pressure. Most systems rely on gravity to get enough pressure to move the water.

The speed of on-site installation is quite fast due to the small space requirement. Just use the housing unit, you don't need to fix any parts. All you need to do is install it into the system and prepare the device for use. Performance Although the filter disc is large in size, it can still perform operations. The smallest filter unit has a very large filter system. Some filters have flow rates as high as 500 liters per second. ·Flexibility You can easily adjust the filter to meet specifications.

-

Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China