Different Types of Wire Mesh

Wire mesh is an incredibly versatile material that is used in various industries, from construction to agriculture, security, and even in DIY projects. Whether you're building a fence, reinforcing concrete, or making an industrial filter, choosing the right type of wire mesh is essential for durability, functionality, and cost-effectiveness. In this guide, we’ll explore the different types of wire mesh, their applications, and their benefits to help you make the best choice for your project.

What is Wire Mesh?

Wire mesh is a material made from strands of metal wire arranged in a grid-like pattern. The wires are woven or welded together to form a mesh, which is available in a variety of sizes, shapes, and materials. Wire mesh is used in a wide range of applications, from supporting structures to providing security, filtration, and reinforcement.

Types of Wire Mesh

There are several types of wire mesh, each suited for specific tasks. Let’s dive into the most common types and their primary uses:

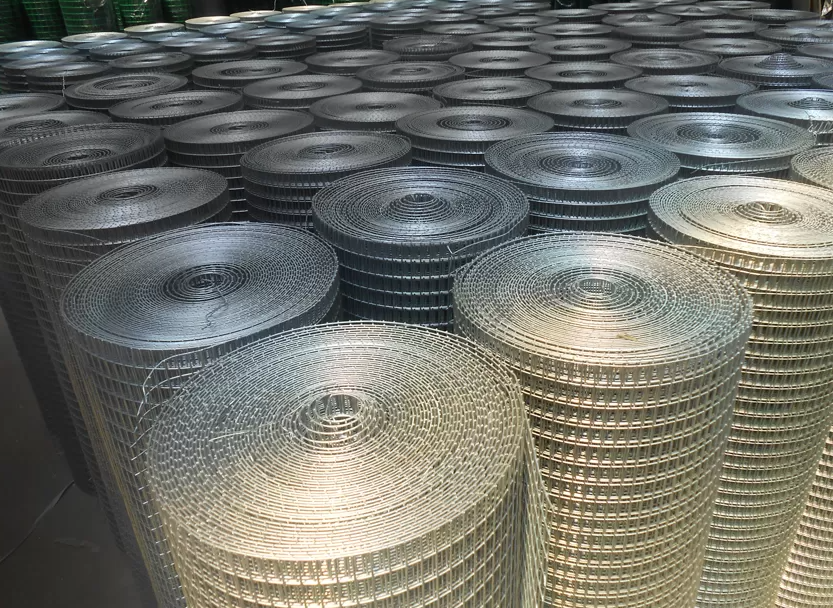

1. Welded Wire Mesh

Welded wire mesh is made by welding the intersecting wires at each joint. This creates a solid grid structure that is highly durable and strong. It is commonly used in construction, fencing, reinforcement, and for agricultural purposes.

Applications:

Concrete reinforcement

Residential and commercial fencing

Animal enclosures (e.g., chicken coops, rabbit cages)

Construction site safety barriers

Benefits:

Highly durable and resistant to deformation

Provides a smooth, uniform grid for easy handling

Available in various wire thicknesses and sizes

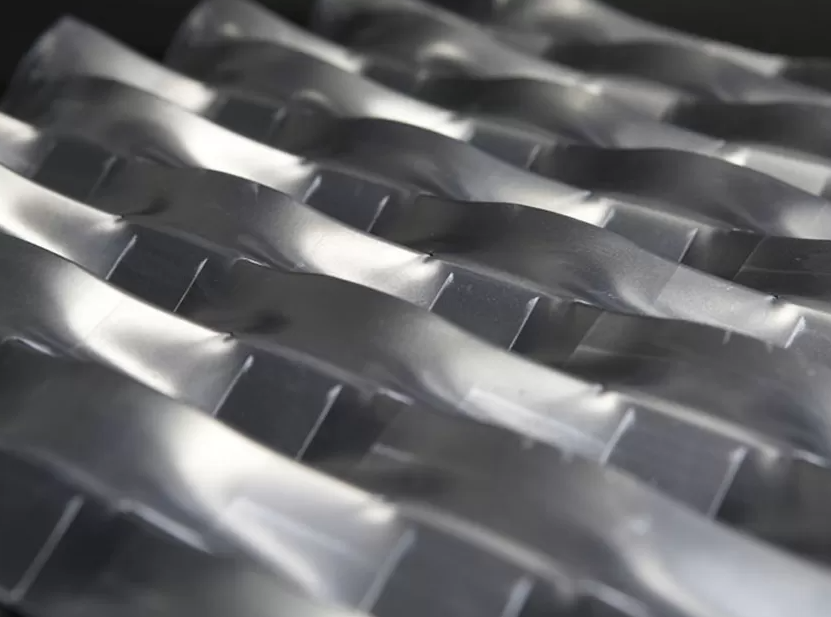

2. Expanded Metal Mesh

Expanded metal mesh is made from a single sheet of metal that has been slit and stretched to form a diamond-shaped pattern. Unlike welded wire mesh, it has no joints or welds, which makes it a continuous sheet of metal. This type of mesh is strong and resistant to corrosion and is used in a variety of applications.

Applications:

Security fencing

Grates and flooring

Wall partitions

Decorative metalwork

Benefits:

Lightweight but strong

Resistant to rust and corrosion

Good airflow and visibility

3. Chain Link Wire Mesh

Chain link wire mesh is one of the most common types of wire mesh used for fencing. It consists of interwoven steel wires that form a diamond-shaped pattern. This type of mesh is widely used in both residential and commercial settings due to its security and ease of installation.

Applications:

Security fences for residential and commercial properties

Sports field enclosures

Boundary markers for large properties

Animal enclosures

Benefits:

Cost-effective and easy to install

Durable and resistant to weather conditions

Provides good visibility while maintaining security

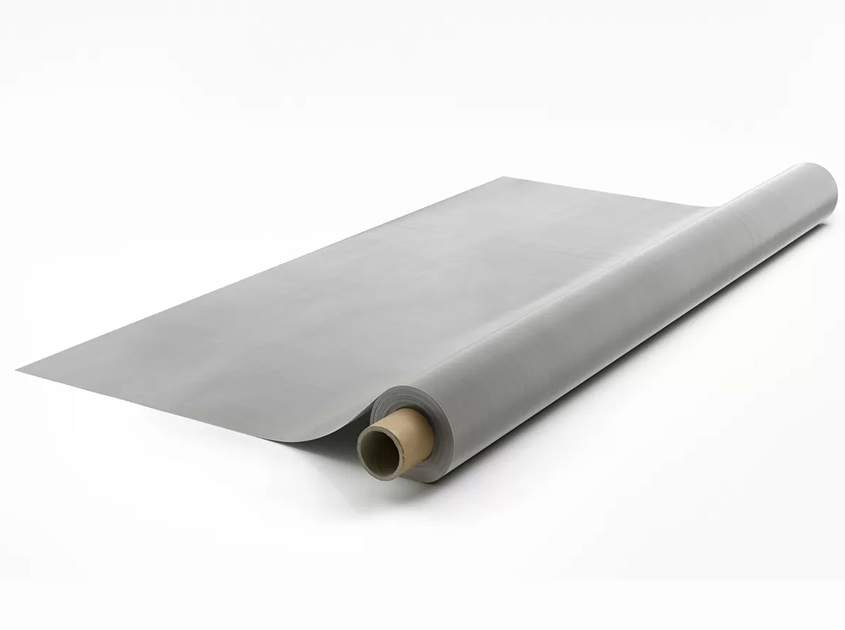

4. Stainless Steel Wire Mesh

Stainless steel wire mesh is made from high-quality stainless steel wire, which is resistant to rust, corrosion, and high temperatures. It’s an ideal choice for environments where the mesh will be exposed to harsh chemicals, extreme weather, or high temperatures. Stainless steel mesh is often used in industries like food processing, filtration, and chemical manufacturing.

Applications:

Filtration systems

Industrial and food processing plants

Reinforcement in concrete structures

Security barriers for high-risk areas

Benefits:

Highly resistant to corrosion and heat

Long lifespan in tough environments

Non-reactive, making it safe for food and medical applications

5. Square Wire Mesh

Square wire mesh is similar to welded wire mesh, but the wires are arranged in a square grid rather than rectangular or diamond-shaped. This type of mesh provides an even distribution of strength and is ideal for applications where uniform spacing is required.

Applications:

Screening and sieving

Animal cages and enclosures

Reinforcement in construction

Support for plants in gardening

Benefits:

Strong and durable

Uniform grid spacing for consistent results

Available in various wire thicknesses for different purposes

6. Hexagonal Wire Mesh (Chicken Wire)

Hexagonal wire mesh, often referred to as chicken wire, is made up of hexagonal-shaped openings. It is typically made of thin wire and is lightweight, making it easy to handle. This mesh is primarily used for agricultural purposes and lightweight applications.

Applications:

Chicken coops and poultry enclosures

Protecting garden plants from animals

Landscaping and erosion control

Creating small animal pens

Benefits:

Flexible and easy to manipulate

Cost-effective for lightweight uses

Provides adequate protection for small animals

7. Welded Wire Mesh Panels

Welded wire mesh panels are pre-assembled sections of wire mesh that are welded together at the intersections, forming a grid. These panels are convenient for quick installation and are available in various sizes and wire gauges. They are often used for fencing, reinforcement, and as a support structure in construction projects.

Applications:

Fencing for properties, parks, and farms

Reinforcing walls and floors in construction

As a framework for concrete pouring

As a barrier or divider in industrial settings

Benefits:

Quick and easy to install

Highly customizable with various sizes and wire gauges

Stable and resistant to heavy loads

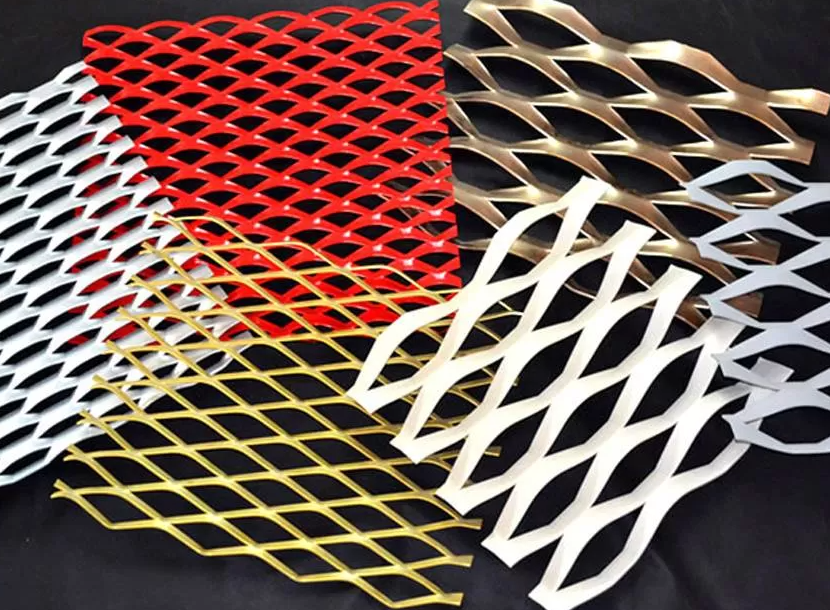

8. Decorative Wire Mesh

Decorative wire mesh is used when the primary goal is to enhance the aesthetic appearance of a space while still offering some degree of security or functionality. This mesh is available in a variety of patterns, colors, and materials, making it ideal for use in decorative partitions, furniture, and interior design projects.

Applications:

Interior partitions and room dividers

Decorative screens for gardens or balconies

Furniture design

Architectural elements like facades and railings

Benefits:

Visually appealing and customizable

Available in different materials like brass, copper, or stainless steel

Lightweight and easy to install

How to Choose the Right Wire Mesh?

Choosing the right wire mesh for your project depends on several factors:

Purpose: Determine whether the mesh is for security, filtration, reinforcement, or decorative purposes. Different types of mesh will offer different levels of strength, flexibility, and appearance.

Material: Depending on the environment, select a material that is resistant to rust, corrosion, or extreme temperatures. Stainless steel is ideal for high-durability needs, while galvanized steel is commonly used for general-purpose applications.

Size and Gauge: Consider the spacing between the wires and the wire gauge. Smaller spaces and thicker wires provide more strength and security, while larger spaces and thinner wires are more cost-effective for lighter applications.

Budget: Wire mesh comes in a wide range of price points, so factor in your budget when selecting the material and type of mesh. Some specialty meshes may cost more but provide better durability and functionality.

With the right wire mesh, you can enhance the functionality, security, and aesthetic of your project. Whether for industrial, agricultural, or decorative purposes, understanding the different types of wire mesh will help you make the best decision for your needs.

Have More Questions Please Contact Us

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

-

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China