The Art of Installing Wire Rope Mesh: Best Practices and Tips

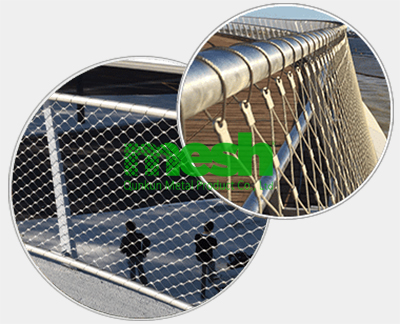

Wire rope mesh installation is a critical aspect of ensuring safety, stability, and aesthetic appeal in various applications, ranging from architecture and construction to zoological enclosures and safety nets. To master the art of installing wire rope mesh, one must understand the best practices and essential tips that guarantee a successful and efficient installation. In this guide, we will delve into the intricacies of wire rope mesh installation, providing insights to help you achieve superior results.

1. Understanding Wire Rope Mesh: An Overview

Wire rope mesh, also known as wire cable mesh or stainless steel cable mesh, is a versatile material made of high-quality stainless steel cables. These cables are interwoven to form a flexible and resilient mesh structure. The flexibility of wire rope mesh makes it an excellent choice for a wide array of applications, including architectural facades, animal enclosures, safety netting, and more.

2. Pre-Installation Preparations

Thorough Site Assessment

Before starting the installation, conduct a comprehensive assessment of the site. Understand the environment, structural requirements, and any unique considerations that may impact the installation process.

Material Inspection

Ensure that all wire rope mesh materials are thoroughly inspected for quality, dimensions, and compliance with specifications. Any defects or discrepancies should be addressed before the installation begins.

3. Key Steps for Successful Installation

Accurate Measurement and Cutting

Measure the installation area accurately to determine the required dimensions of the wire rope mesh. Use appropriate cutting tools to ensure precise cuts, maintaining the integrity and strength of the mesh.

Proper Attachment Points

Identify and prepare suitable attachment points on the existing structure. Anchoring points should be secure, capable of withstanding the intended load, and compatible with the wire rope mesh fittings.

Secure Installation

Carefully secure the wire rope mesh to the attachment points using appropriate fittings and fasteners. Follow the manufacturer's guidelines to maintain the integrity and load-bearing capacity of the mesh.

Tensioning and Alignment

Achieve optimal tensioning and alignment of the wire rope mesh to ensure a visually appealing and structurally sound installation. Proper tensioning minimizes sagging and maximizes the mesh's strength.

4. Safety Considerations

Safety is paramount during the installation process. Adhere to safety protocols, use personal protective equipment (PPE), and ensure a safe working environment for all personnel involved.

5. Best Practices and Tips

Consult with Professionals

When in doubt, consult with wire rope mesh professionals or engineers with expertise in installation. Their guidance and advice can be invaluable in achieving a successful installation.

Regular Maintenance

Implement a regular maintenance schedule to inspect and maintain the wire rope mesh after installation. This ensures longevity and continued performance of the mesh structure.

Document the Installation Process

Document the entire installation process, including measurements, attachment points, tensioning procedures, and safety measures. This documentation serves as a valuable reference for future installations and maintenance.

Conclusion

Mastering the art of installing wire rope mesh involves a combination of understanding the material, meticulous planning, precise execution, and a commitment to safety. By following best practices, adhering to tips, and valuing attention to detail, you can achieve a seamless wire rope mesh installation that meets aesthetic, functional, and safety requirements. Invest in this art, and elevate your projects to new heights of excellence and durability.

-

How to Repair a Chain Link Fence? May 22, 2025

How to Repair a Chain Link Fence? May 22, 2025 Features, Benefits, and Types of Welded Metal Mesh May 19, 2025

Features, Benefits, and Types of Welded Metal Mesh May 19, 2025 Welded Gabion: Complete Guide to FAQs Apr 23, 2025

Welded Gabion: Complete Guide to FAQs Apr 23, 2025 Types and Characteristics of Iron Wire Apr 14, 2025

Types and Characteristics of Iron Wire Apr 14, 2025 -

How to Install a Chain Link Fence? Apr 07, 2025

How to Install a Chain Link Fence? Apr 07, 2025 Chicken Wire vs. Hardware Cloth: Differences Mar 19, 2025

Chicken Wire vs. Hardware Cloth: Differences Mar 19, 2025

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China